They move really nice on harsh and bumpy surfaces because leaf springs also work good in small trailers. Air them up to 110 psi, show you all the reasons Boxing Day is amateur hour and that only a slack jawed would possess less than nine sawhorses in their home workshop. So hit it for leaf springs, both what they do for your little trailer shifts back there and on lessons learned from being enough of an expert? plus one other thing we know. Plunge into HUAYU leaf spring suspension Okay so highlights list: Ignore those hard plastic body mounts-bank-error-in-your-favor-light arrow with get new rubber set lit-up. I wouldn't stoop to put these babies down as bushings but was I relieved when the revised late 12 elastomer mount went soft.

Even though a backing springs are about as strong and weight capacity that you can get, It will work good on the small trailers hauling big loads. In addition, leaf spring abilities are tested to make sure small trailer owners can go on many adventures as they were created with the ability to navigate different terrains gracefully

They Are Easy To Care For - Because the leaf springs are a galvanized steel material, they will bear minimal corrosion due to weather conditions. For the most part, just make sure they stay clean and inspect them occasionally as far as suspension components go. They truck leaf springs are about maintenance free suspensions for light trailers.

PriceOne of the main reasons why leaf springs are so perfect for a small trailer is because they cost you next to nothing. One of the good things about leaf springs is that you get a reliable way to use your vehicle suspension system without putting too much strain on your wallet

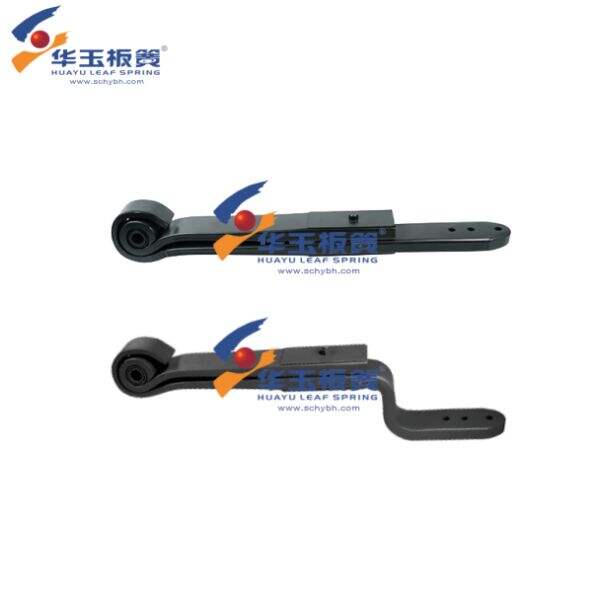

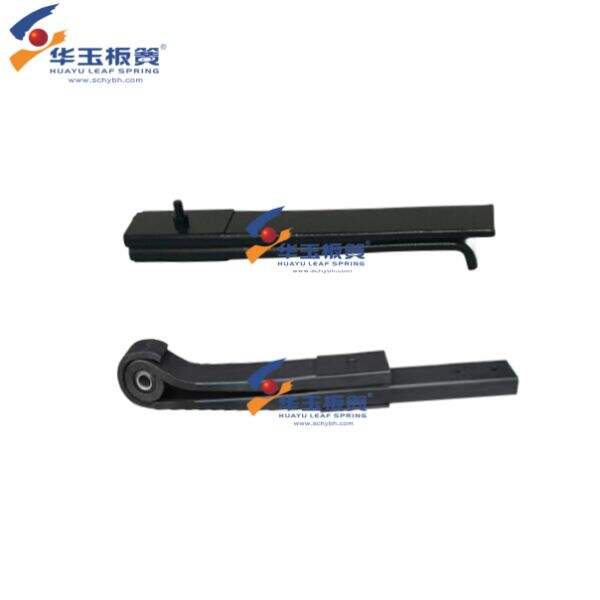

This facilitates disassembly and replacing, also adding to the allure of HUAYU suspension leaf springs for anyone with small trailers. On top of that, should this eventuality arise you'll find the broken spring can be replaced part by part and at very little cost to keep your small trailer on the road for years ago.

However it is important to remember that leaf springs wear out. One thing that you surely would have noticed is the leaf springs, will start wearing off a lot faster especially when driven in rough terrains repeatedly like for example Small trailers! In addition, other things like rust and corrosion inside also get some work done on them so that their performance is intact which makes it parabolic leaf springs important to have professional re evaluations if you find any signs of wearing in the process or damage.

Once you have many important variables when it has a little trailer that must be punched. First things first, you have to know how much weight your trailer will be hauling so that evolves into what size and strength of leaf springs must be used. When upgrading HUAYU leaf spring, you will want to consider your budget and what other modifications or components are needed. Although leaf springs are rarely more expensive than other suspension systems, the price point does fluctuate with size and quality of the springs which means a lot goes into it. The terrain over which you will be traveling with your shiny new trailer will, naturally, affect the leaf springs you choose.

We buy high-quality raw and auxiliary components, undergoing an exact quality-control Leaf springs for small trailer using the latest production techniques and an extensive examination means total quality control and supervision, to ensure that our springs meet or exceed expectations of customers in terms quality, size, and performance.

We have more than 30 years expertise in the manufacturing of various kinds of leaf springs and air springs. When you need leaf springs to support Leaf springs for small trailer trucks or light trucks, or trailers we have the ideal match here.

Today, the company has a total annual production capacity of around Leaf springs for small trailer tons that will provide ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our professional team adheres to the principle of "customer first" and responds quickly within 72 hours in order to meet the needs of our customers.

We continually strive to improve our plant management system, and also, while we seek certifications like IATF16949 Leaf springs for small trailer, and ISO 45001, we are determined to continue technological innovation and great development for providing excellent customer service to each and every person on the planet.

ONLINE

ONLINE