In trailers, particularly single-axle designs, slipper springs are a vanguard of the suspension system. They take the rattle and roll out of driving, meaning while you're barrelling down the road at 60mph your suspension is able to make minor adjustments via these springs for less vibration being transferred back into whatever load has been placed inside! In this guide, we will talk about: What are slipper springs and how do they work The benefits of upgrading to a trailer with Slipper Springs How to choose the right Slippery Spring for your vehicle Step by step how you change Slipped Springs from its own simple-to-install-Job Common questions about slipping springs and their troubleshooting steps.

First, consider slipper springs which will collectively satisfy a type of leaf spring suspension found in most trailers. It is a stack of thin, flat metal plates that are pressed tightly together. These leaves compress and expand when the trailer is loaded, producing a more comfortable and reliable ride. They are so named due to their slipper-like shape.

While all other leaf springs anchor on both ends to the trailer, only one side of each slipper spring is mounted... keeping your suspension system connected at a single end; arrayed such that it operates underground or beneath through tires when in motion. As the trailer goes over a bump, the free end of that spring slides laterally in one piece bracket surrounding it.ensuring travel through impacts without bouncing. When the stopping force is removed, this returns potential energy to a slipper spring which will immediately release again in such as way so that it stops any side-to-side nodding of your trailer.

Why You Should Consider Upgrading To Slipper Springs For Your Trailer

There are multiple benefits of using slipper springs when you upgrade your boat trailer. First and foremost, because they provide a more stable ride that results in less cargo threat. Now, the slipper design on Slipper springs gives you a dampened cushioning effect between your trailer and towing vehicle to reduce road shock and vibration being transmitted over conventional leaf spring suspensions. Moreover, due to their simple nature and size, slipper springs are generally more robust than other leaf spring systems with less need for replacement.

There are a few things to consider when choosing slipper springs for your vehicle, such as load weight and the type of trailer being used. The size of the slipper springs are also a factor to consider: how long, wide and with how many leaves. While a greater amount of leaves on the tandem slipper spring is indicative of strength, it also might create a stiffer suspension that may not be suited for every vehicle.

Guide on How to Replace Slipper Springs on Your Trailer

Start by jacking up the trailer and take out your wheel

Squeeze the U-bolts and spring hangers to remove the old spring.

Remove the tired old spring and check your bushings and shackles for wear, replacing them as needed

Put in the new slipper spring and install one end of the Spring Hangers to Frame.

Lower the Trailer: Before you head on to your trip, drop down the trailer and test it using those new springs.

Slipper springs are a common design for trailer axles, but they wear down over time and lose their support. If you notice that your trailer does a lot of bouncing or swaying as you drive it then this option would be especially important. Another problem could be that the springs began to rust and as they corroded, it made them also break. Simple maintenance steps such as cleaning and lubrication of the springs can easily alleviate these concerns.

Ultimately, slipper springs are pieces of the suspension system that your trailer rides on to absorb shocks and help protect whatever it is you plan on pulling down behind your vehicle. Choosing slipper leaves can produce a variety of advantages, such as improved stability and increased life. Selecting Slipper Springs When selecting slipper springs, you will need to consider the load weight of your trailer and what type it is for. You should also take into account spring specs such as width gaps Problems with Slipper Spring: If you have any major issues, replace or repair the part before it causes a costly problem.

We continually strive to improve our plant management system, and also, while we seek certifications like IATF16949 slipper springs, and ISO 45001, we are determined to continue technological innovation and great development for providing excellent customer service to each and every person on the planet.

We purchase high-quality raw and slipper springs components, undergoing a strict quality certification process, the use of advanced production equipment and thorough testing means, total quality control and oversight to guarantee that our products meet customer expectations in terms of size, performance and appearance.

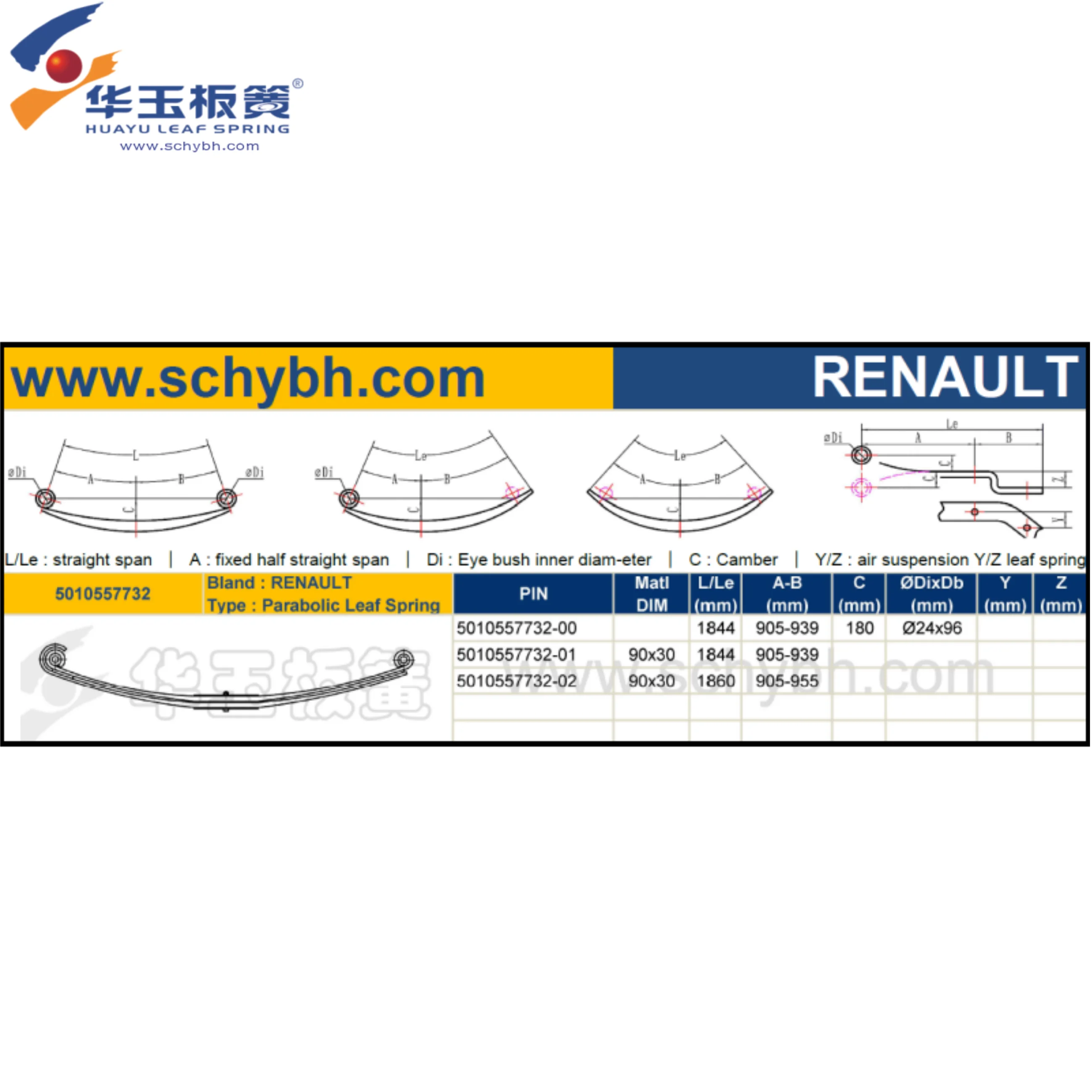

slipper springs over 30 years of experience, we excel in the production of different types of air suspension links such as parabolic leafspring as well as traditional leaf springs. If you need leaf springs for heavy-duty trucks as well as light trucks or trailers You can find the perfect match here.

Today, the company has a total annual production capacity of around 30000 slipper springs, we have a large supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our experienced team adheres to the principle of "customer first" and responds swiftly within 72 hours in order to meet all customer needs.

ONLINE

ONLINE