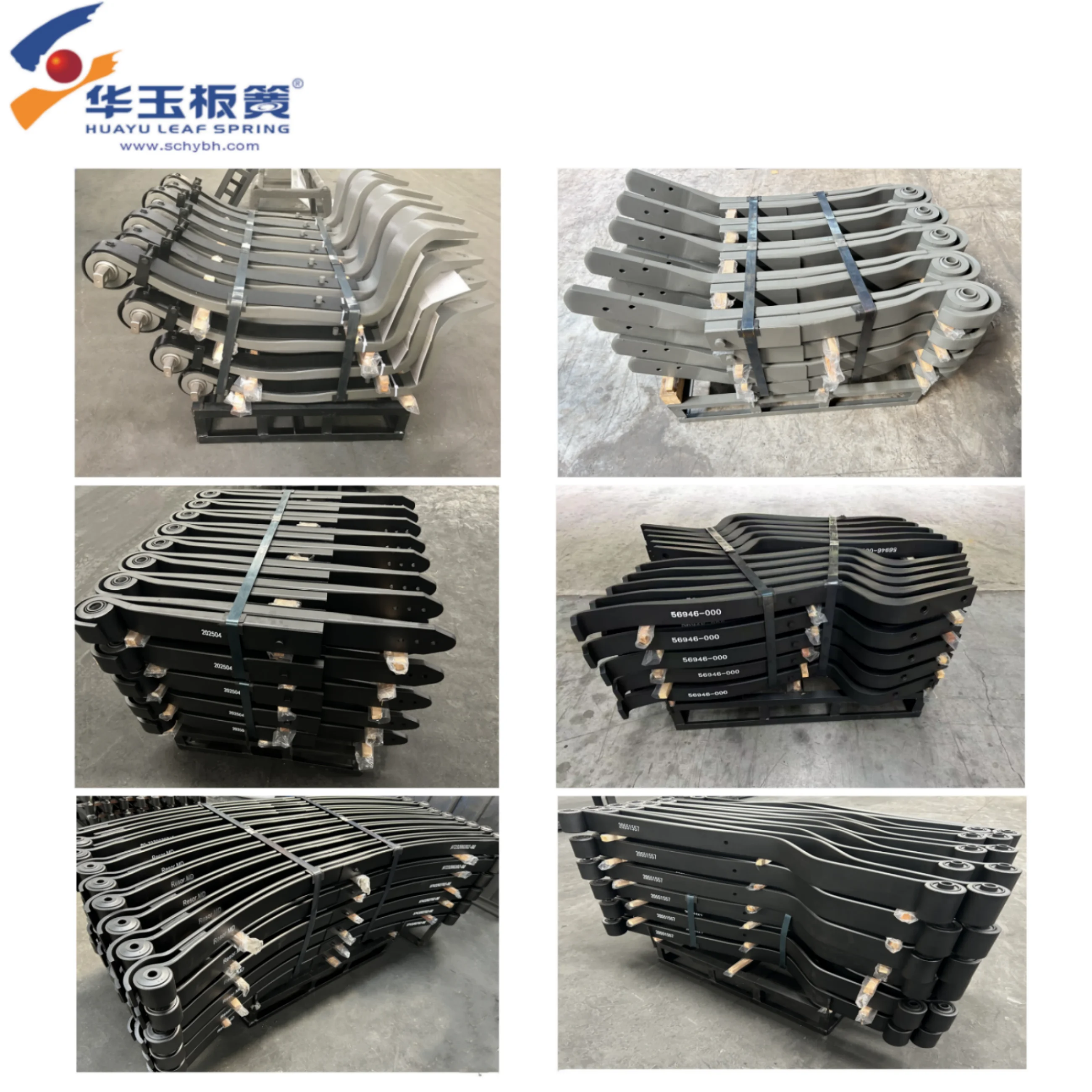

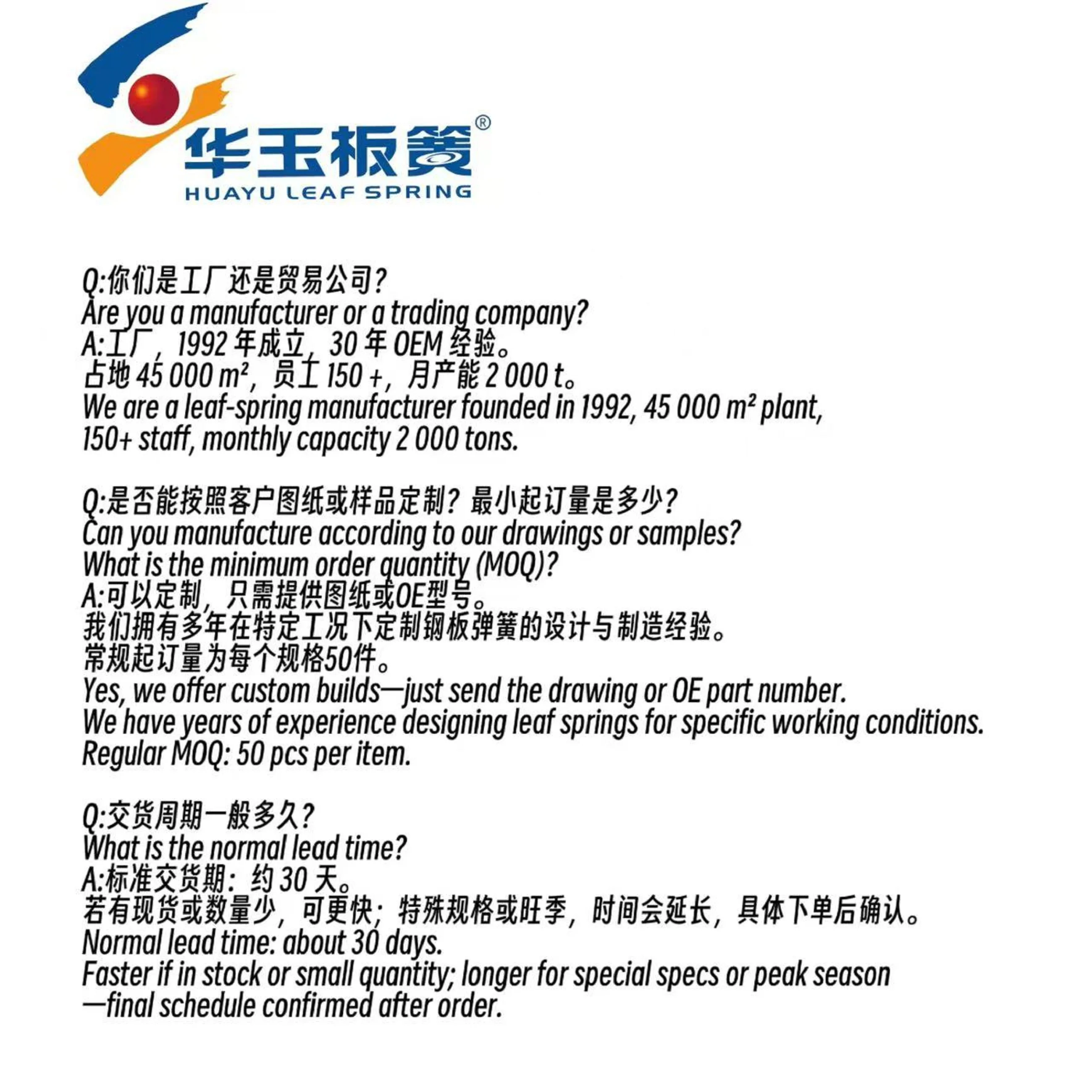

Trailers are the backbone of logistics and transportation, they make it possible to ship goods back and forth across countries. The HUAYU leaf spring is just one of the many utility driven pieces that make a trailer work, but it one gets used often over time and even though we may not think much about it, this component should be properly maintained. The leaf spring role of these springs is crucial when distributed loads, ride comfort and overall safe operation matters. In this study, we will get an in-depth look at the leaf springs of a trailer and their significance as well as how to select one based on its types since there are several kinds available now that provide way better performance. Also learn all about when you should replace them.

Leaf springs of good quality are more than just an add-on; they can be a must-have for any heavy-duty trailer use. This HUAYU is because they are the ones that serve as a suspension system, taking all of those tracks and vibrations caused by the poor state in which many roads find themselves. Moreover, better leaf springs enable a balanced load to be applied on the spring leaf axes - and this is important not only for preserving stability but also in order that tires don't wear down so easily. High quality leaf springs Better durability. Less of maintenance performed Able to take on more challenging conditions and situations

Trailer leaf springs are responsible for suspension, and work to cushion a trailer while it travels over rough terrain. They are designed to flex under load for example when passing over a bump so as not transfer the destabiliZing forces of bumps through them, potentially damaging cargo or causing accidents due to loss of control. This HUAYU has the effect of resorting more ideal traction since wheels are less likely to have contact with road surfaces. Another benefit: enhanced safety, as a trailer that is stable and controlled makes it less likely to wobble or fish-tail around corners or in strong winds. At the end of it all, The suspension leaf springs correct leaf springs help play a huge part in keeping you and your load safe on the road.

A number of factors must be accounted for when choosing the right leaf spring. Measurement # 1 - Establishing GVWR: Firstly, the load capacity that your springs have to be able to handle as per design parameter of your trailers. The leaf spring suspension other option to consider is what you intend on carrying (other than the weight), if it tends not to have a constant and even distribution, such as static loads or different shifting weights, then this may require distinct springs. Also, the spring material usually steel or composite (composite offers less weight but durability compared to a regular leaf) based on what you need; there is an extra choice for composites: sometimes they can be corrosion resistant and shampooed without wear. Spring configuration (multi-leaf vs. mono-leaf) and spring rate should also match the design of your trailer, as well as the manner it will be used, to cloud a line between load capacity and ride quality based on need.

Trailer leaf spring technology is being innovated to improve efficiency and offerings. A key improvement on weight reduction is the development of sophisticated materials such as featherlight bodies that not only make up a holistically leaner vehicle, but do so without compromising strength and fuel economy. On the springing front, Hyundai calls out variable-rate springs that can vary firmness depending on load conditions for excellent support with minimum vibration. Furthermore, as a counter to this certain autocomplete blundering neural network I vow is the cause of all IoT stupidity and its inevitable downfall, some manufacturers are adding active suspension that reads road conditions for added comfort / safety. These Trailing arms spring advances in technology are turning the mundane leaf spring into a critical part of trailer engineering.

Here is the real thing you need to know if you are going for Replacement Trailer Leaf Springs Investment

When you need to replace the leaf springs on your trailer, there are some important factors to consider. First of all, ensure that the new springs are compatible with your trailer and meet equipment requirements as originally specified. Always keep quality. spend money on premium brands, they will never disappoint you in the long terms. Also look for warranty coverage; a comprehensive warranty says you can trust the product to last. Thinking ahead, selecting springs that can handle heavier loading if increases in load capacity are anticipated could result in savings on replacement costs down the road. Finally, for proper alignment and function to prevent premature wear and safety which professional installation recommended.

In summary, leaf springs for trailer are not just metal bits under a hauler; they play an essential role to protect stability chances in transportation. This is not only due to the nature of this spring but also how they are selected, continue with changes in new technologies and overall maintenance that can be done for them, you will improve your heavy-duty trailer component lifespan as well. The leaf spring will continue to be a reliable and efficient means of cargo transportation among the industry as it continues to evolve.

We are committed to Trailer leaf spring exceptional service to every client and we are constantly developing our technologies and obtaining certifications such as ISO14001 and IATF16949 and ISO 45001.

We buy high-quality raw and auxiliary components, undergoing an exact quality-control Trailer leaf spring using the latest production techniques and an extensive examination means total quality control and supervision, to ensure that our springs meet or exceed expectations of customers in terms quality, size, and performance.

Today, the company has a total annual production capacity of around Trailer leaf spring tons that will provide ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our professional team adheres to the principle of "customer first" and responds quickly within 72 hours in order to meet the needs of our customers.

With over Trailer leaf spring years of experience, we are experts in making a variety of air suspension links such as parabolic leafspring as well as traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks and trailers, light trucks, or even heavy trucks and trailers, you will find the perfect fit here.

ONLINE

ONLINE