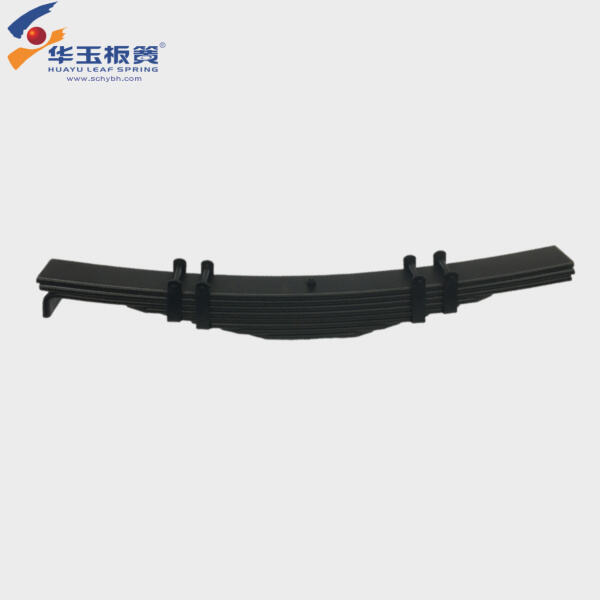

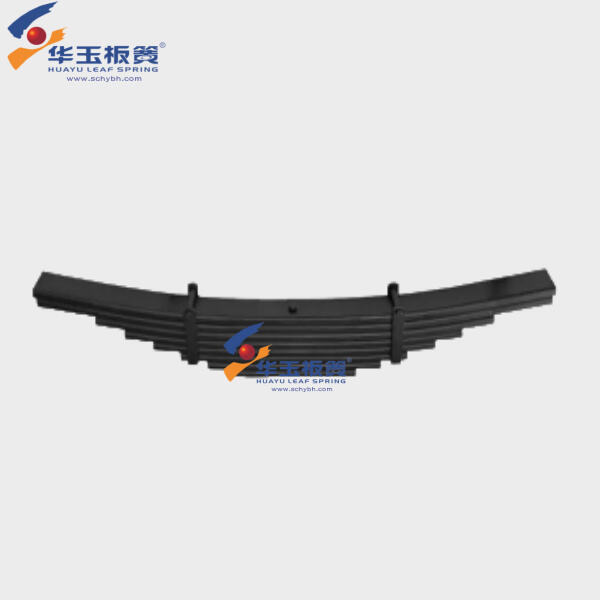

A principal leaf spring is an essential part of vehicle suspension that works for a smoother and safer drive. This spring is the biggest of the bushings in a suspension program and seems like an for a longer period curved metal construction consisting largelyd from specific levels. These layers have strong metal clips that will keep the memory foam in place. What the main leaf spring does is that it has to take all of the weight and bumps on a road.

This helps ensure that your main leaf spring stays in good shape longer and ensures the best performance. Although this unit is very reliability and long lifespan it should be checked occasionally by certified mechanic to see for any wear or damage. This also in turn, will further improve the lifespan of your suspension system by keeping nice and clean free from debris. Such repair or replacement must be carried out promptly to avoid damaging the suspension system and, consequently, other parts of the vehicle.

The main advantage of leaf spring suspension systems is that they have a simple design with respectable load weight holding capability. Also, they are maintenance and repair-friendly. But these systems also have their short-coming. The major downside is they are rigid, and this leads to a bit of an uncomfortable ride. Also, they dont even have the ability to change on different driving scenarios. Main leaf spring suspension systems do well carrying large loads, but may not be the best option for vehicles that travel over rough terrain frequently.

There are many things to take into account when considering if a main leaf spring suspension system is right for your vehicle. Well, first up consider how you meant to use the automobile. And if heavy load carrying is an issue, then some solution based on a main leaf spring system can be considered. In contrast, if your driving includes a lot of tough roads or different conditions other suspension systems could be more suitable. Additionally, take into account the external costs of maintenance and repairs when comparing main leaf spring suspension systems because though they can stand up to much more punishment than a packed style system, if one does break it will potentially cost you several times what some helper springs may.

Problems also sometimes occur with main leaf spring suspension systems, like the metal clips holding the layers of a spring together coming loose or breaking. This can reduce its ability to bear the weight of a vehicle. In these situations, you would have to change the clips. The other common issue is simply the general degradation of the spring over time, leading to less absorption and a rattlier ride. It is important to ensure the safety, and efficiency of your suspension system by replacing these components as soon at they faultfgets.

Our springs are constructed from premium raw materials and other material. We employ main leaf spring manufacturing techniques, sophisticated testing methods, and 100% quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

Our skilled team is committed to be a leading ODM as well as an main leaf spring service provider. They follow the premise that "customer is first" and can respond within 72 hours.

main leaf spring continuously strive to improve the management of our plants and also, while we seek certifications like IATF16949 ISO14001, and ISO 45001, we are also committed to continuous technological innovation and superior technology in order to provide top-quality customer service to each and every person across the globe.

With over 30 years of expertise, we excel in making a variety of air suspension links, main leaf spring leaf springs, and traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks as well as light trucks or trailers You can find the perfect fit here.

ONLINE

ONLINE