Leaf springs are made by stacking flat pieces of metal, called leaves. Eyes: Originally meant to hold the leaves together these are just clamps. The leaves are mounted to the car's frame and axle. The leaf spring is what connects a vehicle's wheels with the body of geneeral motors co;">

Great video explaining GM<a href=… The wheels position is defined by the space of time when wheel crossed a bump. However, as the car moves up and down this spring is being compressed meaning that it becomes shorter and squished so to say. The purpose behind this compression is to counteract the blow from a bump and prevent the car from bouncing endlessly.

Parabolic springs are like all those leaf bounces as it were. These, however, bear a different shape from leaf springs. Parabolic Spring These springs have a curved middle leaf, instead of flat leaves like conventional multi-leaf spring. This unique design helps the spring compress and return with smoother action. Thus, you may have a smoother ride compared to in leaf springs.

Leaf springs and parabolic have different pros cons or one can say that they are suitable at on their place. Many cars have leaf springs, as they are generally cheaper to produce and easier. They are also more durable and will stand the test of time much better provided they have been properly taken care of. The other downside of these springs would be that it can deliver a bumpy ride as opposed to parabolic leaf, which some drivers and passengers may find uneasy.

On the flip side of things parabolic springs are usually more costly and difficult to fabricate. Add on top of that the need for further maintenance than leaf springs to make sure you keep everything working just right. But parabolic springs offer a far superior riding experience and therefore are used mainly in heavy-duty vehicles that require high stability coefficient and some comfort. They are also significantly less rigid than a steel frame, giving them the ability to more evenly spread weight and provide support for heavier loads without impairing ride comfort.

Maintaining Leaf & Parabolic SpringsLeaf springs and parabolics need maintenance to ensure they are kept fully serviceable. If necessary, oil the springs and look to inspect any visible wear or breakage as well. You must also keep the springs clean and free of dirt, as accumulated dust can lead to corrosion which will damage them.

This leads to another important point: before we delve too deep into leaf and parabolic spring specifics, it'd be good for us to learn about compression travel and rebound. As the car hits a bump, it compresses the spring closing that gap between leaves. That compression helps to absorb the shock from hitting a bump, and stops the car bouncing around too much in response.

One such example is as follows: over the center of a bump, there are no wheel inputs and when the wheels come back down on their way to maximum extension or compression (too unbuilt-to-ride-car-y), we have our first major spring rebound. It results in the leaves going back to their position under which makes everything smooth and calm for those who are sitting inside.

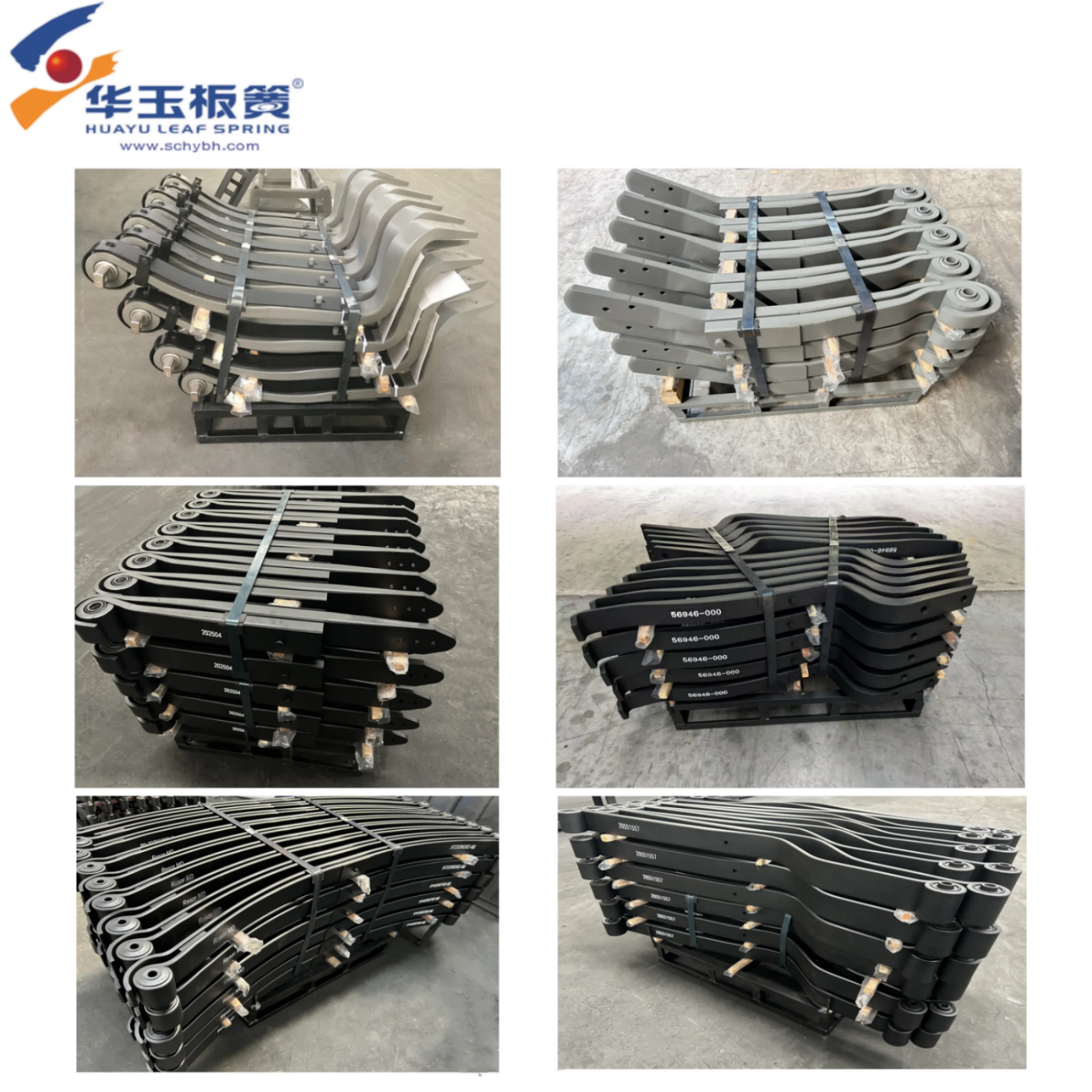

Today, the company has a total annual production capacity of around 30000 tons leaf and parabolic springs ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds promptly within 72 hours to address every customer's needs.

We leaf and parabolic springs more than 30 years experience in the manufacture of a variety of leaf springs and air springs. You can find leaf springs for light trucks, heavy trucks or trailers.

We are leaf and parabolic springs to providing excellent service for every customer and we are constantly developing our technology and achieving accreditations like ISO14001 or IATF16949, and ISO 45001.

leaf and parabolic springs purchase only the highest-quality raw materials and auxiliary material, following a a strict quality certification process that makes use of the most advanced production techniques and an extensive testing means, total quality control and supervision to make sure that our springs surpass expectations of customers in terms quality, size, and performance.

ONLINE

ONLINE