How to Choose the Right Trailer Springs for Your Needs

Correct trailer springs are essential when you own a trailer in order to have the best possible transportation experience. They are essential in helping support the load of your cargo to keep your trailer upright and riding smoothly down that long stretch of tarmac. Explore the core aspects when selecting trailer springs, frequently occurring problems that can plague them and just why you should each.

To the quest to your best trailer springs, it's critical first emphasis may be that the burden of one's cargo. HUAYU t trailer leaf spring comes in a series of strengths from light to heavy-duty applications. Choosing springs that are rated just above the weight you expect to routinely carry will provide top-of-the-line performance.

Another key consideration, the type of spring required. The three most common types of trailer springs are leaf, coil and torsion wave. They were used at that time and are still often in use because of their sturdy construction, making the leaf springs an excellent choice for heavy loads. Meanwhile, coil springs are less commonly used and more costly but ideal for lightweight trailers and should not be utilized with heavy loads as they will struggle to maintain shape under pressure. All stainless steel torsion springs are more durable and resistant, making them a decent alternative to conventional trailers.

Like anything mechanical, HUAYU trailer with leaf springs can experience problems during their service life. Some common issues a trailer owner may experience and how to troubleshoot:

1. Sagging: When your springs are sagging, they may be straining to support a heavier load than what is recommended. If this is the case, try spreading the load or adjusting springs with a higher weight limit

2. Incorrectly Wearing: On one side of the spring, uneven wear could be caused by axle out-of-alignment. This MVP can mitigate this issue if the alignment problem is corrected.

3. Broken Springs - Overloading and aging wears out springs causing them to break down. The recommended fix is to replace the broken spring with a new one of same type and weight capacity.

Quality trailer springs provide several benefits when installed, such as:

1. Increased Safety: Trailer leaf springs help stabilize the trailer on a level road surface and make it more stable by reducing sway to prevent rollovers.

2. Better Handling: Ride with confidence by choosing the appropriate truck trailer springs for your camper, which will boost stability and eliminate side-to-side wobble when laden.

3. Greater Comfort: As HUAYU leaf spring on a trailer helps to reduce the shocks and vibrations that come from moving the truck, you will notice a more comfortable step.

When installing these to eating, it is important to follow the manufacturer's installation instructions carefully. Alignment and installation with the axle, as well as other components is equally important. The maintenance one also needs to perform for preserving the state of these trailer springs so that no issues could occur in this regard as well.

So how do the three different types of trailer springs compare in terms of strength, durability and cost?

1. Leaf Springs: These are the most economical of your spring set ups and will handle a wide range of weight capacity.

2. Coil Springs: More costly than leaf springs, these have a lower weight capacity and are less long-lasting as well.

3. Torsion Springs: They may on the costlier side, but then deliver great strength along with loading carrying capabilities.

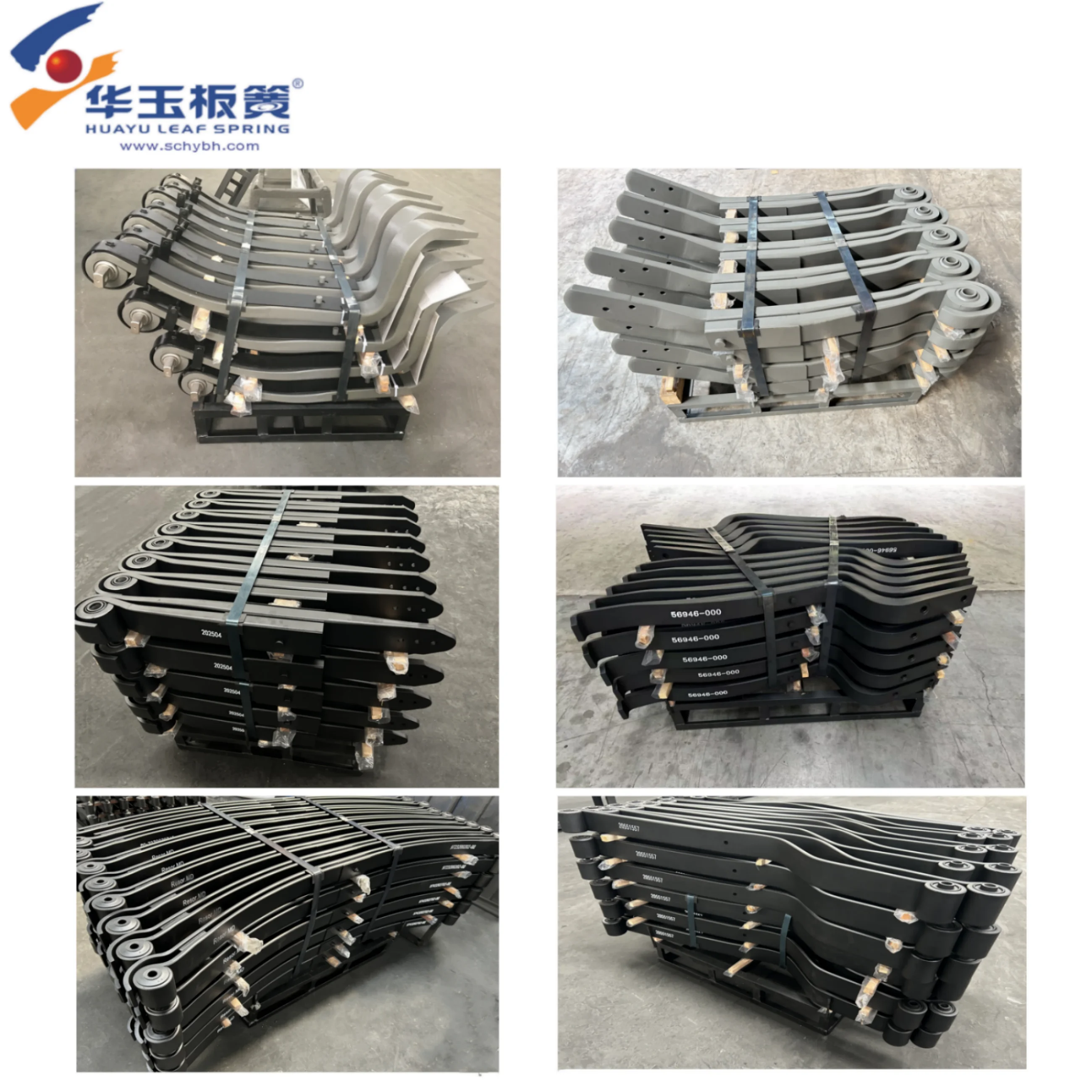

We source Trailer springs raw and auxiliary material, following a an extremely rigorous quality certification process that makes use of the most advanced production equipment and thorough inspection means, absolute quality control and oversight, to ensure that our springs exceed the expectations of our customers in terms of quality, size, and performance.

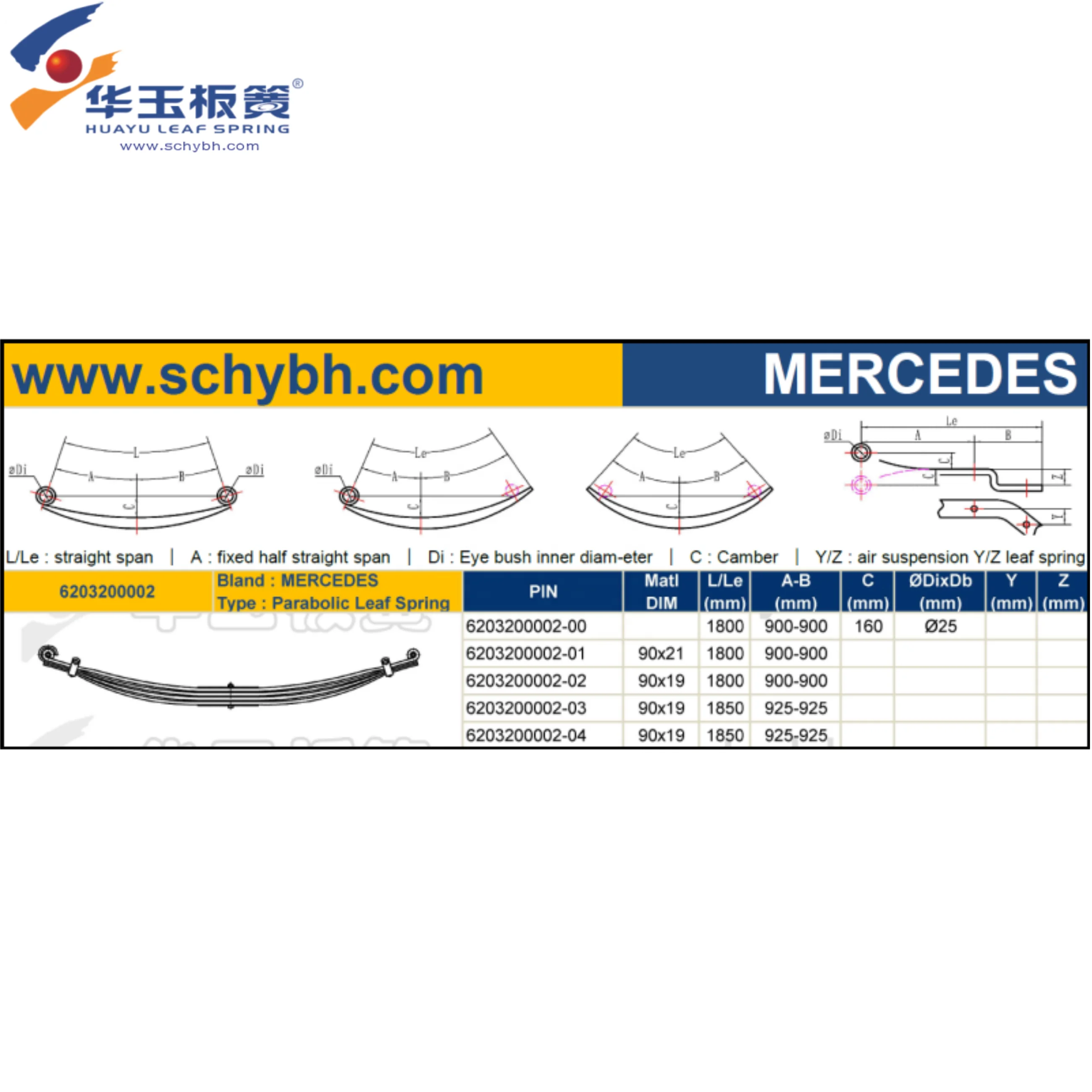

With more than 30 years of experience, we excel in making a Trailer springs of air suspension links, parabolic leaf springs, as well as traditional leaf springs. Leaf springs are available here for light trucks, heavy trucks or trailers.

Currently Trailer springs an annual production capacity of 30 thousand tons, which is a huge supply capability. Committed to become a top ODM, OEM and end customer service provider, our expert team is committed to the concept of "customer first" and responds quickly within 72 hours to meet every customer's needs.

We're committed to providing outstanding service to each customer We are committed to continuously Trailer springs our technology and getting certifications such as ISO14001 and IATF16949 and ISO 45001.

ONLINE

ONLINE