Semi elliptical springs are also known as parabolic leaf springs and these offers a lot of benefits to the vehicles. These help ease the drive, specifically over bumps or uneven terrain. This article will take you through how these springs operate to be an excellent way of carrying heavy loads, how they have evolved over time and what maintenance would entail.

Semi elliptical springs are operated through an elastic potential energy. And you just said that when a spring is compressed or tension, it gets squashed and elongated respectively. In the compressed or elongated state, while it is deformed, the spring stores energy. So when you take forces away from pushing or pulling, the spring will unleash that stored energy. It is the capability of releasing and storing energy that allow these springs to absorb shocks and vibrations while driving. Therefore, over bumps of the road, this component will assist to smooth out some of the shock by means similar absorbtion.

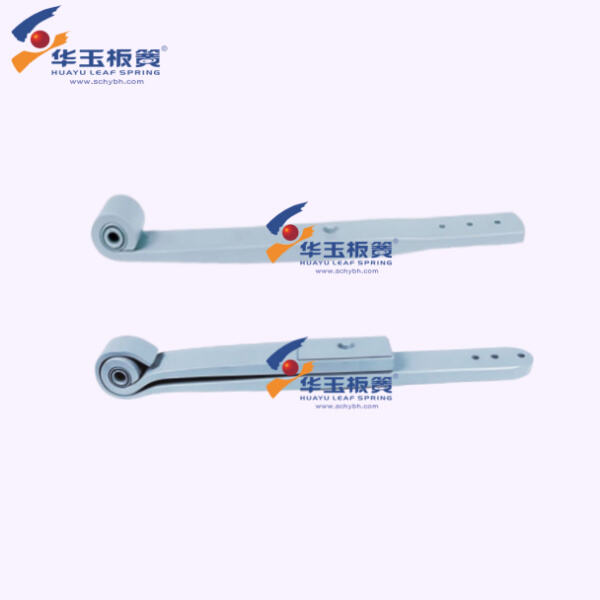

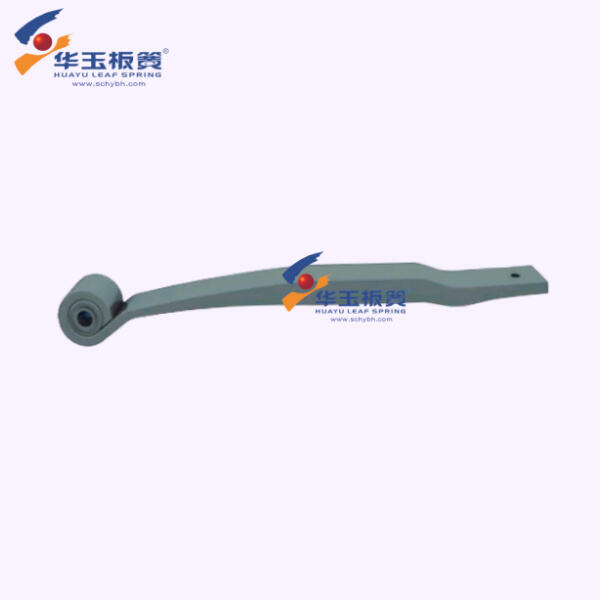

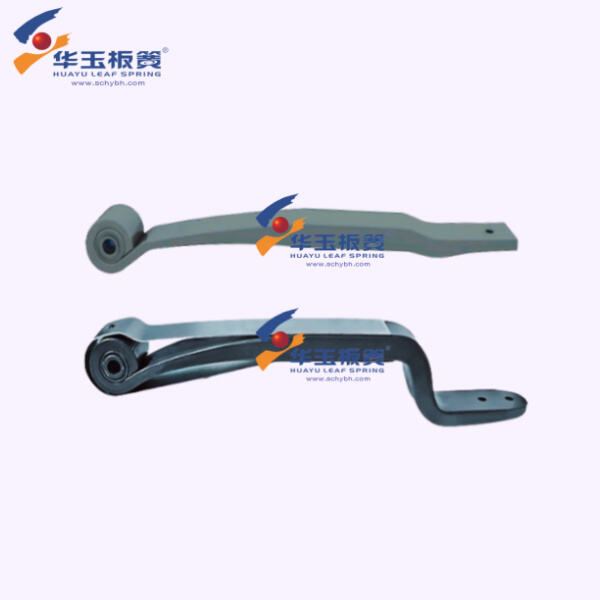

These springs are designed especially for heavy purposes as it is one of the strongest materials and can withstand a lot of weight. Commercial vehicles must carry heavy items on the road, which is where leaf springs play a significant point. As you drive over bumpy roads the springs help to soften these bumps and jolts, which makes driving your car more comfortable. Semi elliptical springs are something that you can see being used in some bigger vehicles such as trucks, buses and even few kinds of construction equipment. That sturdy construction helps make sure nothing is going to slip and slide around when you load it up with heavier stuff.

Everything from the design and performance of semi elliptical springs has changed over time. These springs were once made from wood and employed regularly in horse-pulled lodges. This enabled passengers to experience a much smoother journey. And, in the 1900s these started getting made from steel as technology improved greatly and became much more powerful for car use than wood beams. Today, these springs are manufactured using an even more robust material than the original spring steel; a type of alloy steel that significantly increases their load-carrying capability. These days they remain as much of a necessity in large vehicles, to supply everybody aboard with the safety and comfort.

As compared to other types of springs, semi elliptical spring has positive aspects and also some demerits. This advises the net plus aspect is that these springs have terrific strength, intense durability in addition to can manage a hardiness of loads. Despite this, there are several disadvantages to using them as well. However, on the downside over time, it can weaken or become fatigue in a metal -congress of these same parts making this sort useless. If you neglect them, they may not be as effective. At the same time, there is a question of their operational reliability and safety: semi-elliptical springs require constant monitoring as they are gradually compressing.

The maintenance of semi elliptical springs is a big factor in keeping your car running at its best You can achieve this by keeping a close check on them for wear and tear. Most experts will tell you to replace these springs every 50,000 miles or less if you have any issues or detect damage. InspectionsRegular inspections will catch problems earlier on before they become bigger issues. This is beneficial for the long run, it enhances their performance and longevity. This basic maintenance can extend their life expectancy greatly.

We constantly strive to strengthen our plant management semi elliptical spring, and also, while we seek certifications such as IATF16949, ISO14001, and ISO 45001, we are dedicated to continual technological innovation and great development for providing excellent service to every customer around the world.

We semi elliptical spring more than 30 years experience in the manufacture of a variety of leaf springs and air springs. You can find leaf springs for light trucks, heavy trucks or trailers.

We buy high-quality raw and auxiliary components, undergoing an exact quality-control semi elliptical spring using the latest production techniques and an extensive examination means total quality control and supervision, to ensure that our springs meet or exceed expectations of customers in terms quality, size, and performance.

Today, the company has a total annual production capacity of around semi elliptical spring tons that will provide ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our professional team adheres to the principle of "customer first" and responds quickly within 72 hours in order to meet the needs of our customers.

ONLINE

ONLINE