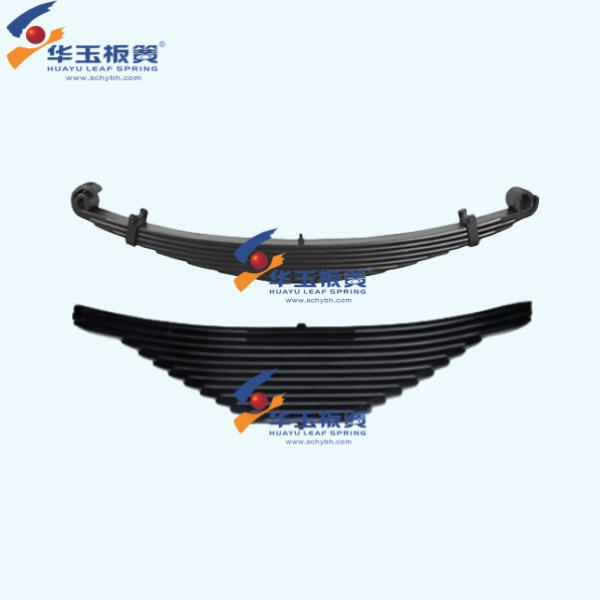

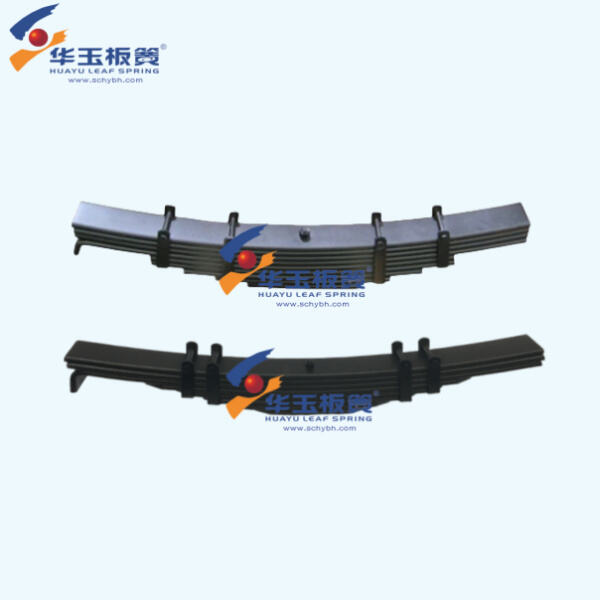

When it comes to truck suspension leaf springs, they are a great part of any truck. They support in stabilization and balancing of truck while it is travelling on road. He notes that they are the curved metal pieces under the truck you see here. They help to keep your truck running straight and in the right place on its own, simply because they hold up a good bit of the weight.

Leaf springs consist of any few slim strips regarding metal (commonly steel) put up to ensure that they will turn into a one system. The bands are stacked on top of each other and then fixed to the frame part vertically passing through the truck. The leaf springs are put to a real test as truck goes over bumps or drives only on rough roads. They also play a significant role in soaking up the impact of hitting those bumps. So when the truck hits a bump, those leaf springs get pushed down. This makes the weight of the truck spread out nicely over those bars (axles are just fancy bars that wheels hang on, really). As the truck rides over a bump, and then once again continue with its upward movement of spring. The bounce helps to stabilize the truck so it does not tip or sway too much.

It is important to select the right kind of leaf springs for your truck Considering the weight that your truck needs to transport The heavier the load, thicker leaf springs are required to hold it. For transporting heavy stuff we suggest some leaf springs that are more thickerbtile yswneensxvz qith stronger properties. Leaf springs also come in various dimensions that include but are not limited to, multiple lengths widths and profiles. You should choose the best fit for your model. In order that your truck is still balanced and stable carrying loads

Meanwhile, to ensure the proper function of your trucks suspension system you must look after its leaf springs. It is imperative that they are checked on a regular basis. Check for cracks, wear or bending. Proper cleaning and lubrication of the leaf springs also aid this. Over time, the springs may become stiff and less responsive due to dirt/grease buildup resulting in spring-rusting for reduced functionality. Whether you see damage or not the best thing to do is just get it replaced as soon as possible so bigger problems don't develop down line if something really does happen LCAs protector isn't enough to protect against. Doing routine maintenance on your truck suspension system will help it to last longer as well, and keep everything nice n smooth.

New leaf springs are a fantastic way to improve the overall performance of your truck. Leaf springs are also better quality and stronger brand new than the stock spring that comes in trucks when they roll off the factory line. This can provide additional strength to improve how the truck tracks on-road. You may also choose custom-made leaf springs, they can be crafted to fit your specific requirements. Although, be sure to familiarize yourself with the various options available. Investigate a variety of brands, and research what springs work for your trucks individual needs.

Over time, leaf springs can encounter issues like any other part of the truck. In another situation the springs sag or go flat();?> It results in the truck sitting lower than it should, which was obviously going to alter how well things handled. If you are experiencing this happening, remedy it by adding another spring or replace the old one with a tougher and stronger leaf. Stiffness is another problem that you may face. Which is why it stays vertical, and the springs do no flex or bend enough to soak up all of the road's bumps. If this occurs, the vehicle can provide a rough and uncomfortable ride. Springs can be very rigid, and applying a silicone spray will help alleviate their stiffness and make them work correctly. Finally, if the leaf springs arent giving enough support during heavy loads on trucks they might start to run low. This can be solved by upgrading to thicker springs that have a higher weight capacity or adding extra leaves (usually called "helper" springs) to give slender OEM spring packs additional support.

We continually strive to improve the truck suspension leaf springs of our plants and also, while we seek certificates such as IATF16949 and ISO14001, and ISO 45001, we are dedicated to continual technological advancement and superior development to provide excellent customer service to each and every person on the planet.

Today, the company has a truck suspension leaf springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

Our springs are constructed from premium raw materials and other material. We employ truck suspension leaf springs manufacturing techniques, sophisticated testing methods, and 100% quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

With over 30 years of expertise, we excel in making a variety of air suspension links, truck suspension leaf springs leaf springs, and traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks as well as light trucks or trailers You can find the perfect fit here.

ONLINE

ONLINE