The Unassuming (But Powerful) Laminated Spring - Did you ever consider about the tiny, but powerful laminates spring? This thin metal strip may appear pretty innocuous, but it holds the key to many machines we encounter every day. Imagine a band, strong but flexible it has layers of metal stacked and melded. Such construction provides the laminated springs with enough rigidity to support a weight yet, at the same time allow them retain their flexibility so they can remained intact and move freely on up-and-down motion.

This particular innovation of laminated springs has been encouraged by the automobile industry and cars use them in their design. Springs which mops up all those shocks and bumps the car encounters in your suspension system. In terms of resiliency, laminated springs are in a league of their own compared to the more standard and traditional steel type which repeatedly retain further than worse tolerances after being subjected to stress. This led to many automobile manufacturing houses capitalizing on the use of laminated springs for upgrading the driving experiences in terms of safety AND comfort.

Special attention needs to be paid due to the several pros of laminated springs while defects are a challenge as well. Engineers have to make sure the layers not only stick together properly, but also that there are no air bubbles or blank spots between themair pockets in any of its (upwards) 27mm xanthan-methylcellulose walls would simply leave part of your spring empty. However, it is equally important to find the right balance of flexibility; overflexibility may compromise strength and prevent realistic movement in a spring.

Engineers use specialized machinery and techniques to combat these challenges by helping maintain layer adhesion. Finally, computer simulations abuse aside the springs performance as a function of pressure and experiment with various levels to determine optimal strength vs flexibility.

The choice of materials is very important in the area of sustainability when it relates to laminated springs. The metals which are traditionally used in these springs are not able to be recycled and this can have a negative effect on the environment when they need to be disposed of. As a result, some business have actually searched for recyclable choices consisting of aluminum and carbon fiber. These materials are not just strong and lightweight, but they represent a greener option as well. Once a spring has completed its life, it can be re-melted and reused lowering the sustainability burdens associated with manufacturing.

So between those factors, the choice of laminated springs or recyclable material comes down to the specifics of use and values. Make sure the product you are selecting can resist to pressure with failure, in such a robust solution go for a laminated spring. However, if you make your choices based on ecology sensitivity, then choose a returnable material spring.

When all is said and done, the best spring for your application can be accurately determined by consulting with a reputable engineer or supplier. With this insight, you can find the perfect mix of strength and flexibility to improve your methods for performance while considering sustainability in environmental impact.

We're committed to providing outstanding service to each customer We are committed to continuously laminated spring our technology and getting certifications such as ISO14001 and IATF16949 and ISO 45001.

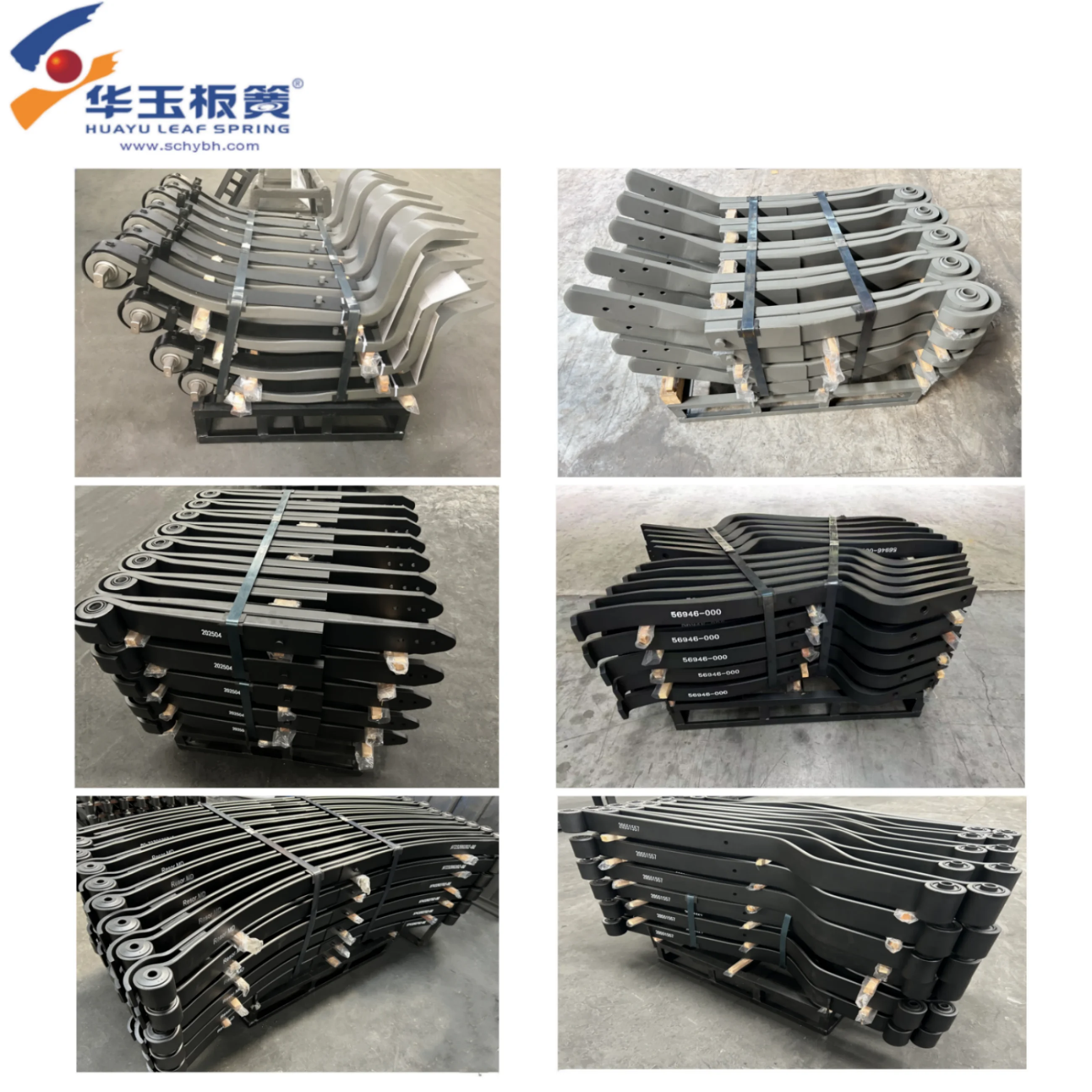

With over laminated spring years of experience, we are experts in making a variety of air suspension links such as parabolic leafspring as well as traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks and trailers, light trucks, or even heavy trucks and trailers, you will find the perfect fit here.

laminated spring purchase only the highest-quality raw materials and auxiliary material, following a a strict quality certification process that makes use of the most advanced production techniques and an extensive testing means, total quality control and supervision to make sure that our springs surpass expectations of customers in terms quality, size, and performance.

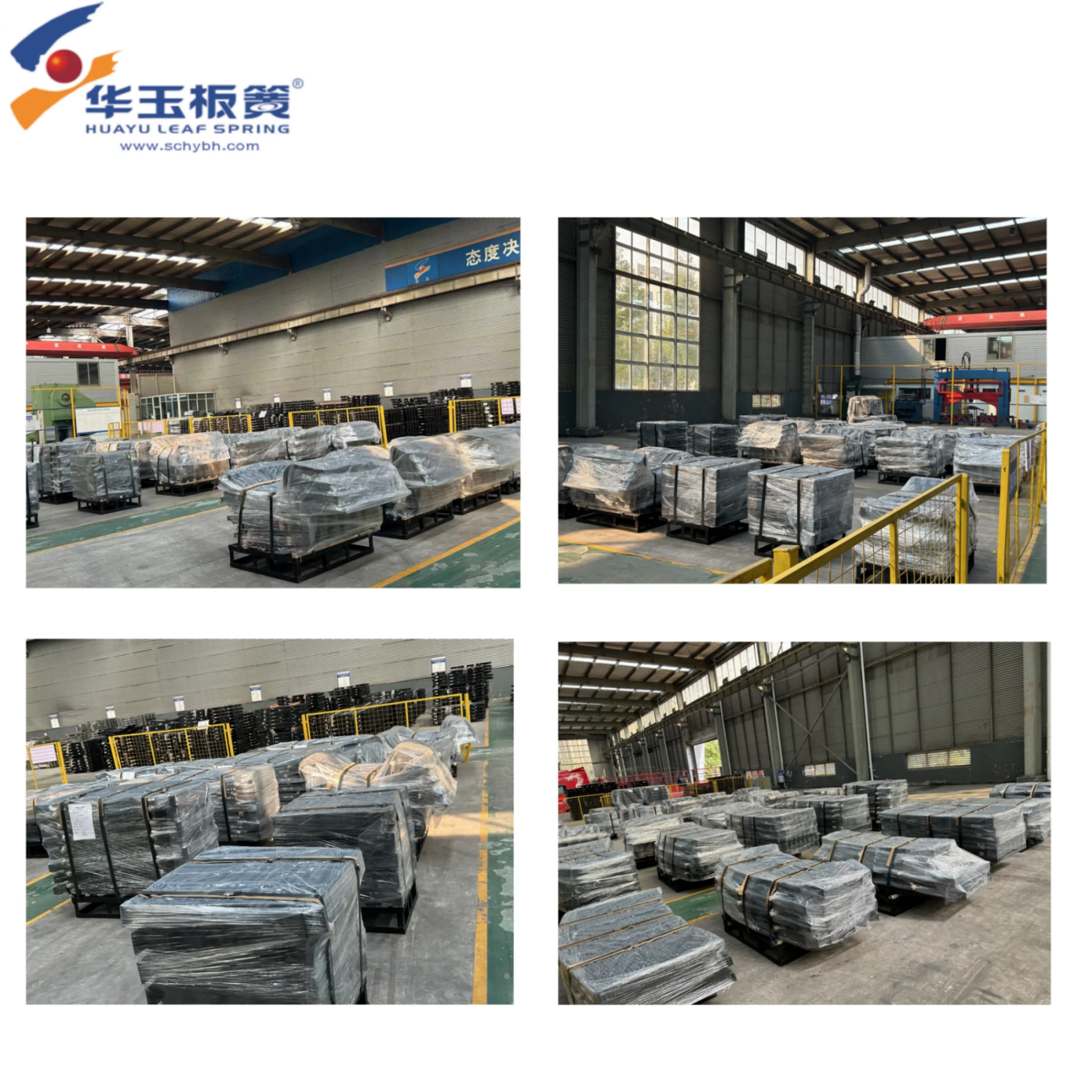

Today, the company has a laminated spring annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

ONLINE

ONLINE