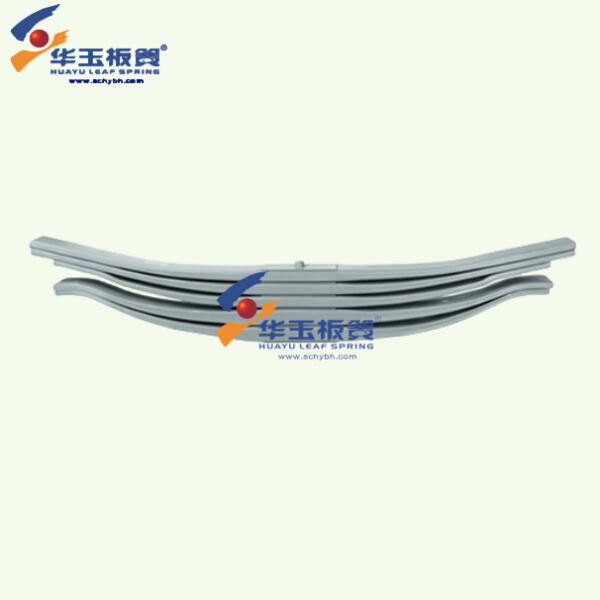

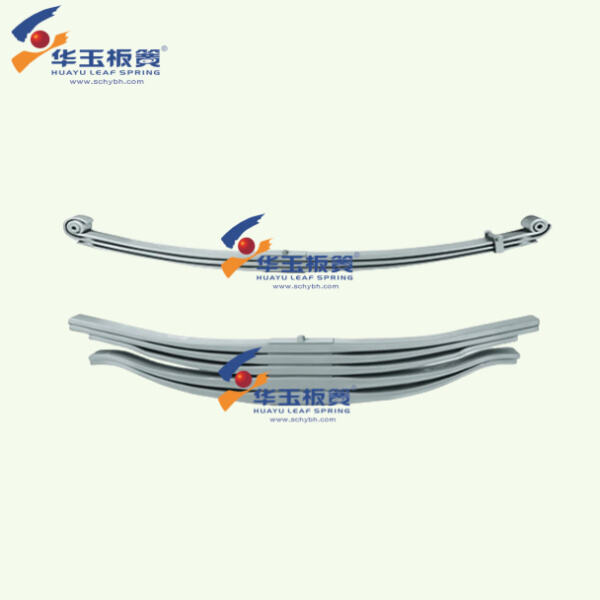

These are a far cry from the regular leaf springs employed in your average family car, however. Series 3 parabolic springs have important differences to ordinary examples of this simple suspension type. Instead of flat and straight, these springs are curved like a smile. The angled shape enables the springs to work more effectively so that the car can stay planted on bumps (compression) and dips in the road.

Series 3 parabolic springs, which are actually built tougher but lighter. Reducing weight overall means the car rides and handles better, while also consuming less fuel. A less heavy car is lighter, and thus easer to control, can easily react better for the motorist.

Of course, there are other benefits of switching to series 3 parabolic springs for your Land Rover — Volume production The obvious reason is the performance boost that they bring. For example, they reduce body roll (you have the RX's wallowy ride to thank for that). Body roll is the sensation you get when your car leans to one side while turning. These springs help the car have more control and keep it flatter when you race or whip around turns quickly.

Another added bonus is that series 3 parabolic springs deliver a more plush overall ride. They are made to be more compliant over bumps in the road than traditional springs. This will translate into less shaking and bouncing within the ride, which is consider much more comfort for everyone in the car.

There is nothing unusual about series 3 paraphrased leaf springs, except for their design. Conventional leaf springs are constructed from a bundle of individual thin metal sections stacked together. While springs are typically take up speed bumps, they can sometimes bring a bouncy sensation and add to an unpleasant experience on roads that aren't perfectly smooth.

Conversely, series 3 parabolic springs are forged from a single curved piece of metal. That makes it more able to behave like a spring and be squished but still return back. Therefore, the drivers have a smoother ride with more stability especially on highways.

Another benefit of series 3 parabolic springs is they last forever, or at least almost. Constructed using much stronger material, these springs are designed for a longer life than traditional leaf springs. That would make them unbreakable, and that means less spending on repairs and replacements.

Today, the company has a series 3 parabolic springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

With over series 3 parabolic springs years of experience, we are experts in making a variety of air suspension links such as parabolic leafspring as well as traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks and trailers, light trucks, or even heavy trucks and trailers, you will find the perfect fit here.

We constantly strive to strengthen our plant management system, as well as gaining certifications such as series 3 parabolic springs, ISO14001 and ISO 45001, we are dedicated to continual technological innovation and great development for providing excellent service to all our customers around the world.

Our springs are made of series 3 parabolic springs raw materials and other material. We employ the latest production technology, thorough inspection methods, and 100% quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

ONLINE

ONLINE