Leaf Springs - "Building You a Better Suspension" Leaf springs are the soul of what Roadmaster does. HUAYU leaf spring provides some structure for the vehicle to ride on top of, and smooth out your ride a little. Over time, these springs can weaken which leads to a poorer-performing truck. One of the best ways to improve your truck's load capacity is by upgrading it with heavy-duty leaf springs, and you'll also get better ride quality, handling as well as overall performance in a much significant manner. We will be discussing in detail the reasons you should upgrade to a heavy-duty leaf spring, which ones are best based on your truck's payload capacity, the importance of maintenance and replacement at regular intervals, whether steel springs really can be replaced with composite equivalents wherever possible as well as installation tips from experts.

While enhanced load-carrying capability is one of the more obvious benefits to upgrading with new, heavy-duty leaf springs. If you regularly move heavy loads or tow a trailer, then stiffer leaf springs should be used as original factory specs would not provide enough support to help with axle-twist. The added weight gets absorbed by the heavy-duty leaf springs so that they do not sag down or hit to road bottom. The result is greater stability, better handling and less chance of damaging the suspension.

In addition to helping the truck carry more payload, installing heavy-duty leaf springs can also help how your overall ride quality. Heavy duty springs are built stronger and offer more resistance against bumps, potholes, or any rough patches you may encounter on the road. Smooth driving here we come. This, for instance, will help to alleviate strain on other parts of your truck including tires and shocks.

Browsing through leaf springs for trucks, specifically looking at the weight capacity expected and the type of usage is another deciding factor. One easy way to figure out how much weight your truck can carry is by subtracting the empty curb weigh from its gross vehicle rate rating (GVWR). This number is the maximum your truck should legally weigh, with passengers and all of their gear.

After learning how much your truck can carry you will be able to select the right additive leaf springs. There are different load capacity heavy duty leaf springs for various trucks and applications. Picking springs that are stiff enough to support your truck is important, but they shouldn't be overly stiff. The suspension system may be damaged with the use of overly stiff springs.

The thing about leaf springs on your truck is that, just like with every other part of the vehicle besides dust particles: they wear out and need to be replaced after time. The rubber elements can dry out and wear down over the years, making them less supportive so that they compress easily into loose material or break apart while driving under load. More regular maintenance, such as cleaning and lubrication should keep your springs from rusting out too quickly, but eventually they should be replaced to ensure a safe and proper functioning garage door.

Visual evidence that you need new leaf springs include saggy suspension, signs of wear and tear or splitting as well your tires wearing down unevenly. If you see any of these warning signs, have your HUAYU auto leaf springs examined by a professional mechanic.

Leaf springs have traditionally been manufactured of metal since it is both strong and cost-effective. Advances in technology have brought composite materials (fiberglass, carbon fiber) into consideration as well. Composite leaf springs are lighter than their steel equivalent, as well as resistant to corrosion while having a higher strength-to-weight including high social benefits.

In addition, steel has the potential to rust and weaken; composite leaf springs are impervious to salt, dirt and road grime that could cause damage over time. Composite materials are also more immune to fatigue, a common problem of steel springs caused by constant bending.

So, these are the instructions we recommend you to follow when installing leaf springs on your truck.

As with installing the HUAYU trailer leaf spring, it is also important to install in all proper procedures for them as well. In general, replacing both leaf springs on one particular side of your vehicle is a mistake that you want to avoid since this can cause the other components in your rear suspension system having uneven wear and get unbalanced. It is equally important to use the appropriate tools and equipment for installation, as well as properly torquing all bolts/nuts in accordance with manufacturer specifications.

And most importantly, adjusting the correct angle of suspension system and a followed by wheel alignment is crucial after installation of new leaf springs. The alignment process sets the tires in position for uniform tread wear and safe driving.

Ultimately, after reading this blog you find that getting your hands on heavy-duty leaf springs is worth the investment for any truck owner out there. It not only improves load capacity, ride quality and process efficiency but also when you replace these parts timely due to wear and damage it is closely related with optimal performance. Same as safety too. With the right leaf springs of weight capacity for your truck, and installed properly you should have a smooth ride as well as worry-free transport.

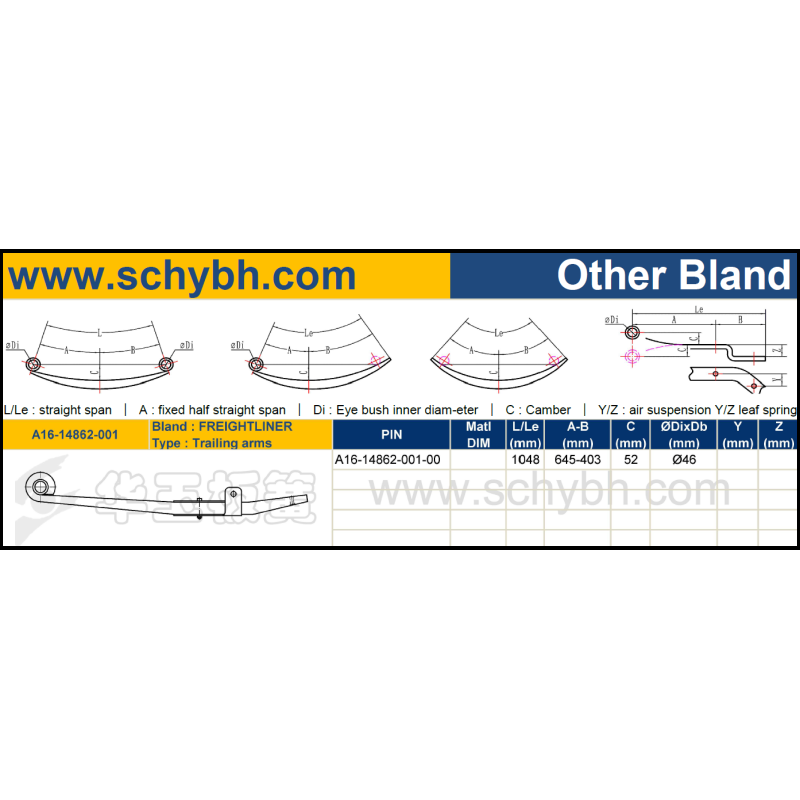

With more than 30 Leaf springs for trucks of experience, we have a great track record in the production of different types of air suspension links and parabolic leaf springs and traditional leaf springs. Leaf springs can be found on this page for light trucks, heavy trucks or trailers.

Today, the company has a total annual production capacity of around 30000 tons Leaf springs for trucks ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds promptly within 72 hours to address every customer's needs.

We are Leaf springs for trucks to providing excellent service for every customer and we are constantly developing our technology and achieving accreditations like ISO14001 or IATF16949, and ISO 45001.

Our springs are made of Leaf springs for trucks raw materials and other material. We employ the latest production technology, thorough inspection methods, and 100% quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

ONLINE

ONLINE