A steel leaf spring is one of those parts. In the simplest of terms, they are a key component that is responsible for enabling you to take on such bumps in style and comfort. Today we would like to dive deeper into leaf springs, what they actually are and how do they function why vehicles need them so badly. By the end of this, it will be clear that how you should take acute care to everything related airlines and leaf springs as because one thing damage leads risk life during drive.

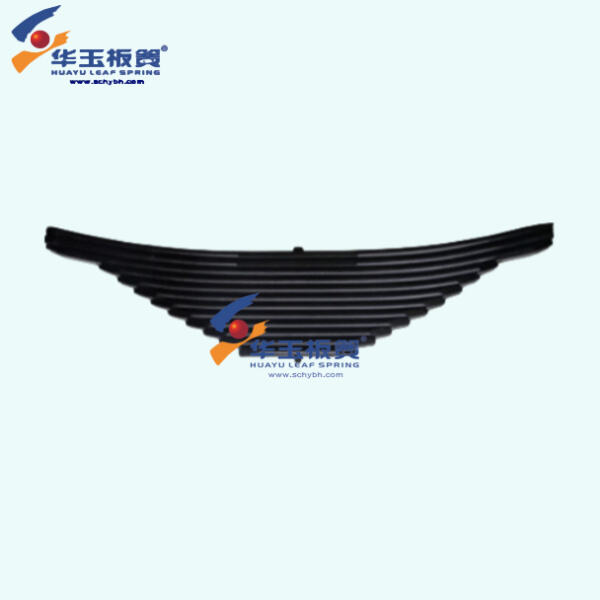

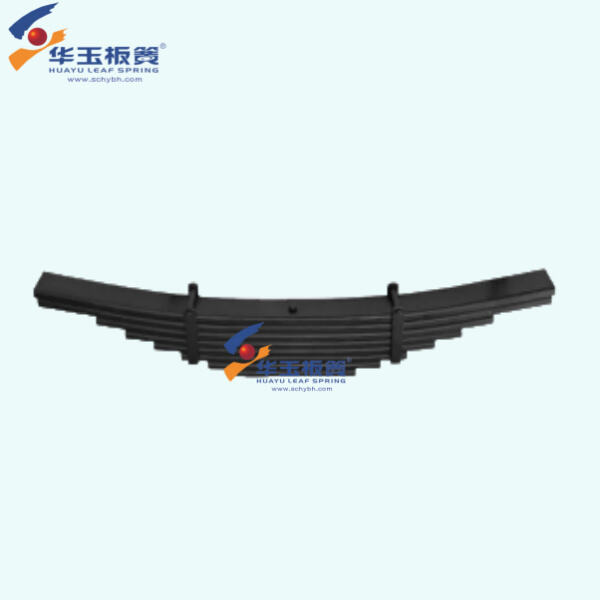

Leaf springs are basically papers of thin sheets of steel kinded in one another like a book. These are commonly known as leaves, which give the leaf spring its name. One end of the leaves attaches to a car's frame, which is essentially its skeleton in vehicle terms, while the other end links up to an axle that assists with turning wheels.

When a car drives over the bump on the road, they squish down under that weight and then spring back up again to their original shape. This helps smooth out the ride and keep it from feeling too jarring. They work to spread the weight of the car evenly, so as not to disturb its balance and stability on different terrains.

Leaf springs are meant to absorb shock from the road and make for a much smoother ride, while on bumpy or uneven surfaces. To absorb the bumps, leaf springs -- yes, they are on a 2018 car in case you missed it-- compress and then release so passengers do not feel like bobbleheads. This spread the weight of the Buick, and used in combination with suspension leaf springs helped to weakly resist leaning (as a side note). This can allow the driver to more easily control their car, especially when turning or driving over bumpy terrain.

Looking out for the leaf spring is an important requirement and any lapse can be dangerous not just to your vehicle, but also those travelling in it. An atttribute where if not taken care of will end up being worn out or brokent over time are the leaf springs. That can make it more difficult for the driver to control, and therefore dangerous when driving. Worn out leaf springs can also leave your suspension unable to effectively absorb shocks, which is going to make for a bumpy ride.

The safety of the litter springs needs to be regularly inspected. Be on the lookout for any damages on the leaves, if they are separated from your car's chassis as well as axle. If you see any issues like corrosion, worn connections etc., it MUST be addressed immediatly to ensure the car is safe on your way.

Semi-elliptical leaf springs : These are curved springs and can be commonly seen in most cars as well on trucks. This is made possible by their design which helps to improve the ride quality.

general leaf springs purchase only the highest-quality raw materials and auxiliary material, following a a strict quality certification process that makes use of the most advanced production techniques and an extensive testing means, total quality control and supervision to make sure that our springs surpass expectations of customers in terms quality, size, and performance.

We general leaf springs strive to improve our plant management system, as well as gaining certifications like IATF16949, ISO14001 and ISO 45001, we are also committed to continuous technological innovation and great development to provide excellent service to all customers across the globe.

Today, the company has a general leaf springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

We have more than 30 years general leaf springs in the manufacture of various leaf springs and airspring. Leaf springs can be found here for light trucks, heavy trucks, or trailers.

ONLINE

ONLINE