For the way cars and trucks move, leaf springs are significant. They are old, and they have evolved over time to assist heavy trucks and trailers.

Leaf springs were used long ago in horse-drawn carriages to smooth out rides. They’ve been refined and altered so that they can adapt well to the vehicles of today, and being sturdy, able to carry heavy items.

Leaf Springs Why Are They Good for Heavy Trucks and Trailers? Among the biggest reasons: They can hold a heavy load without having to bend over too far. This leads to a smooth and quiet ride for everyone inside the car. Leaf springs are also easy to maintain and repair, which is a consideration for companies that operate trucks because it saves them money.

If comparing leaf springs to other spring types, such as coil springs and air suspension, each spring type has its own advantages. Coil springs provide more responsive handling, but leaf springs are better at carrying heavy loads and maintaining a stable ride, particularly on bumpy roads. Air suspension can provide a final comfortable ride but is typically more difficult and costly to maintain than leaf springs.

For trucks that are designed to roam off-road, having an understanding of what problems can occur and how to maintain leaf springs is critical to both safety and performance. Among the gripes riders reported are bending, cracking, rusting, and the results of lower travel quality. Inspecting them and greasing them often can help solve these dilemmas and allow leaf springs to last longer.

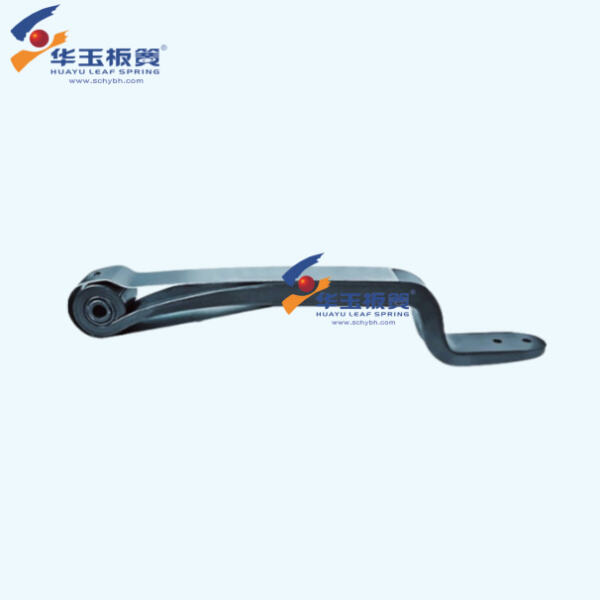

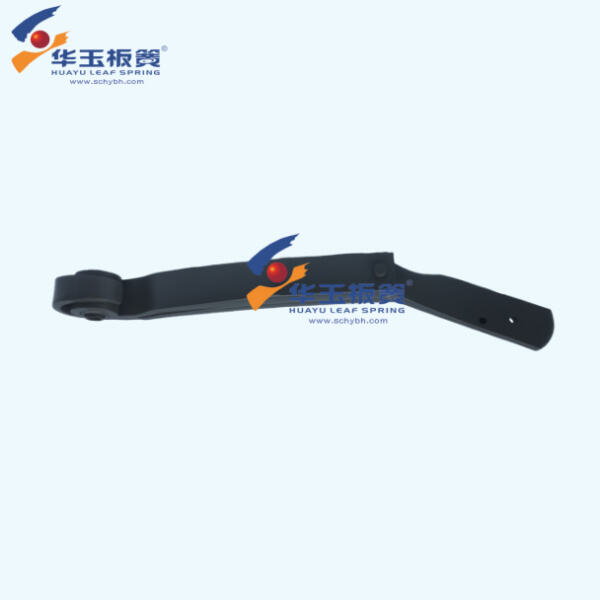

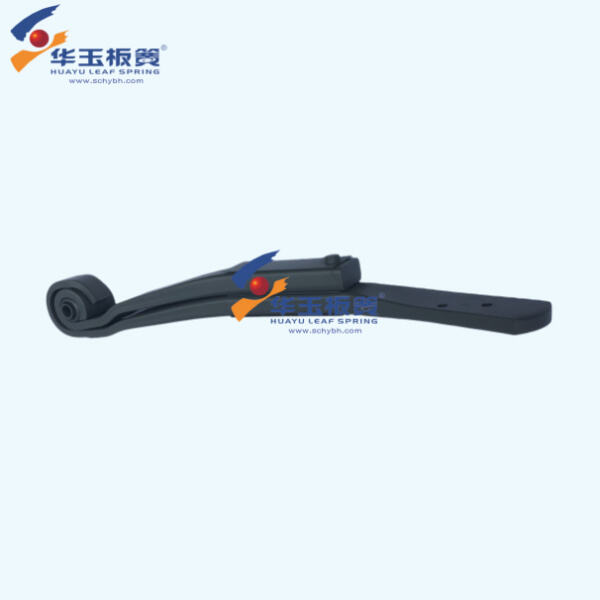

Today, new materials and designs are making leaf springs in modern vehicles better than ever. New models, such as composite leaf springs and parabolic leaf springs, have made them lighter and stronger. These new concepts revolutionized leaf spring usage and made them an invaluable asset in a wide range of vehicles.

ONLINE

ONLINE