In Simple, have you known why your car jumps on ride at the road? The suspension system of course! Your suspension system is critical to your vehicle and its performance impacts both the ride and control of it. This system includes something known as laminated leaf springs, one of its significant components. These special springs help the car bounce better and improve overall ride quality for its occupants.

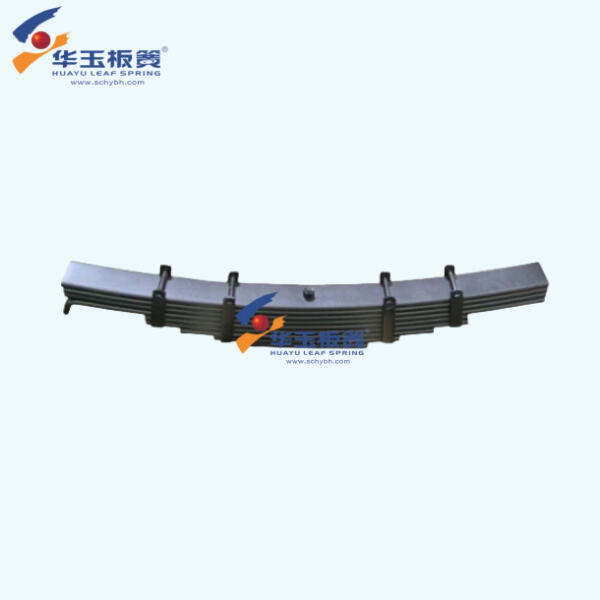

What are under-slung leaf springs in a vehicle? They resemble long iron book leaves that are kept over one another. They are metal leaves that move up and down in order to take away all the jolts and knocks you feel on a bumpy road. This serves to reduce the tendency in a vehicle for so-called "bouncing", which makes things safer and more comfortable.

Another downside is that the leaf spring in this system has been made of a single piece of metal back before, While this design worked, it had its drawbacks. Later on, as technology advanced so did leaf springs which were developed out of laminated leaves. Leaf springs (and especially laminated leaf springs) are carefully layered sheets made of metal. They are far stronger and longer lasting than the old solid metal springs. They can carry more weight, and therefore are sturdier as well provide a smoother experience.

Have you heard of the term heavy-duty truck? Heavy-duty trucks are larger, stronger vehicles that can lead to truck accidents due to their size and load. They carry goods and materials to most of the country, as well as internationally. Due to carrying so much weight, these trucks need a suspension that would be strong enough. Frameworks: Enter the laminated leaf springs!

It is ideal in heavy duty trucks because a laminated leaf spring can provide higher loading capacity and more flexibility, on top of cancelling the noticeable clunking noise that was giving all solid metal springs away. These are ideally built to support heavy loads and the firm weight-bearing ability means a stable drive. It is important because when a truck has items loaded or it contains heavy stuff in the dumpster so, with Balloon Suspension system get work as preventive for extra bouncing of such trucks that ensures safety from affects to driver and at road on others around.

A machine specifically designed for this purpose then squeezes the layers of metal together so tightly that they bond. This is what we call it "heat treating. So when a gun recoil spring is " heat treated", it makes the metal super strong and resilient which is critical to its function as a spring.

Leaf springs have been around for eons, you say? They have been around for over 200 years and we first used them on horse-drawn carriages. Leaf springs were wood rather than metal Back in those days. Wooden springs also helped with this, but they were not as strong and stable as what are now commonplace.

We continually strive to improve our plant management system, and also, while we seek certifications like IATF16949 laminated leaf spring, and ISO 45001, we are determined to continue technological innovation and great development for providing excellent customer service to each and every person on the planet.

laminated leaf spring springs are manufactured from premium raw materials and other material. We employ the latest production technology, thorough techniques for inspection, and complete quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

Today, the company has a total annual production capacity of around laminated leaf spring tons that will provide ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our professional team adheres to the principle of "customer first" and responds quickly within 72 hours in order to meet the needs of our customers.

We have more than 30 years expertise in the manufacturing of various kinds of leaf springs and air springs. When you need leaf springs to support laminated leaf spring trucks or light trucks, or trailers we have the ideal match here.

ONLINE

ONLINE