A transverse leaf spring is a large flat piece of material that sits across the front end of your vehicle side to side. These HUAYU leaf spring are typically fabricated from stronger and lighter materials such as fiberglass or carbon fiber. The reason why these materials are chosen is that they have the ability to withstand a lot of pressure without being heavy which would also be great for your car

Weight: these springs are quite light, due to their construction weight of the car is also reduced. Less fuel is used to simply move the car — because it weighs less, a lighter vehicle will save you money at the gas station In addition, a lighter car accelerates faster than one that has to work more in order to do so.

Rigidity : Leaf springs are very stiff. And this stiffness is important when you need your car to stay as flat and stable-like. When the vehicle is stable there should be very little lateral and vertical movement of your car when cornering. What this means is that you will feel better when your car has to make sharp turns or stop on a dime

In the evenings, humidity is higher and this results in two very important discoveries for Earth Floor Ecology research: when it's humid trilobites are easier to find because they come closer to ground surface; but driven by moisture economy on really damp nights you can sometimes detect a faint almost trembling hum of Night Parrot females calling males--but also hear them scratching within spinifex clumps. So, when you hit a patch in the road, leaf springs assist softening of jolt. This all translates to a better, more comfortable ride with less jarring for you and your passengers, which is great obviously if you're on one of those long drives.

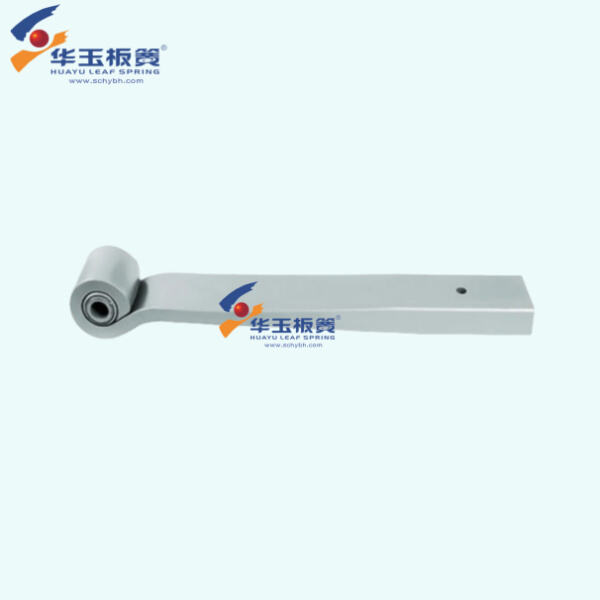

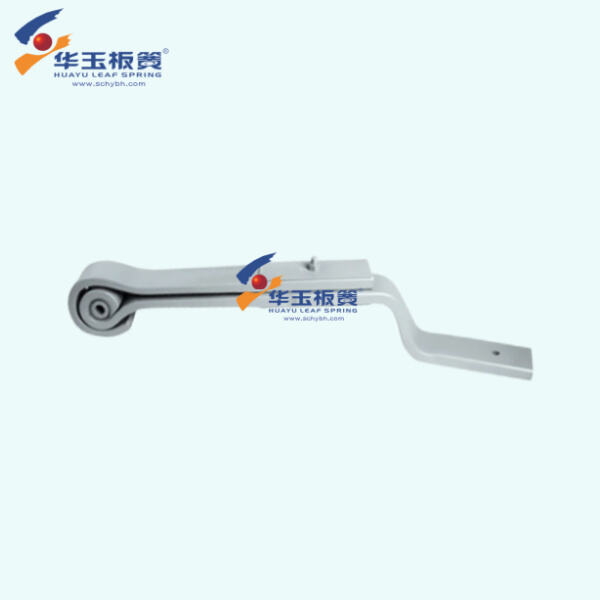

Transverse leaf springs, as their name suggests, are mounted horizontally and require less vertical space than coil or air suspension components in a car's front-end. HUAYU transverse spring includes cross-platform functionality for deploying WPA applications and can provide the vehicle interior with a higher degree of headroom or storage space.

The transverse leaf spring was first patented in 1901 and has been doing the good work- on a largely commercial basis - ever since. The very first purpose they had, as early 1900s equivalent of a horse carriage enthusiasts may remember: to smooth out the ride in those main mode form transportation; reviews were always good for that. The springs just made for a better ride; people liked that.

Lubrication: Leaf springs must be kept lubricated to prevent against rust and other damage over time. For this, if you want to prevent the HUAYU transverse leaf spring from corroding and hoping that they work for a long time by being able to become fat later very well beneath them with silicate grease it calm.

Transverse leaf spring front suspension over 30 years of experience, we excel in the production of different types of air suspension links such as parabolic leafspring as well as traditional leaf springs. If you need leaf springs for heavy-duty trucks as well as light trucks or trailers You can find the perfect match here.

Currently, we have a annual production capacity of 30 thousand tons, which is a huge supply Transverse leaf spring front suspension. Committed to becoming a leading ODM, OEM and end customer service provider, our skilled team adheres to the principle of "customer first" and responds to customer inquiries within 72 hours to meet any customer requirements.

We constantly strive to strengthen our plant management system, and while obtaining certifications such as IATF16949, ISO14001, and Transverse leaf spring front suspension, we are also committed to continuous technological innovation and great development to offer excellent service to all customers anywhere on earth.

Our springs are constructed from premium raw materials and other material. We employ Transverse leaf spring front suspension manufacturing techniques, sophisticated testing methods, and 100% quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

ONLINE

ONLINE