Why Springs Are Important In a Truck and How to Tune It For High Performance

Springs are an essential feature of a truck as these are the components upon which the comfort, load handling and stability depend. These springs have to play a role in the quality of the suspension system that handle shocks, vibrate and height adjustment when loaded. This article will also focus on the importance behind truck springs and how these can be altered to maximize operation.

Comprehending the Importance of Truck Springs

Truck springs which play several important roles such as:-

Carrying the Weight of Your Truck: They would be supporting your truck by carrying all that weight along with ensuring it stays level, no matter how much you are towing

Shock Absorption: Cushioning bumps and rough rads for a smoother ride.

Ride Height: the truck adjusts its height to accommodate whatever it is carrying and ensures the best performance.

Wheel Alignment, tire wear and maintenance: Good alignment can help cut down on the harmony of traction and decrease the uneven tyre heavy.

Ensuring that the springs are properly adjusted is crucial if you want to maximize your truck or SUV performance. In this article, I will show you how to do it step by step.

Pick the Right Springs: Start by selecting springs according to your truck's weight and where you plan on running it.

Set The Freeway Ride Height: Determine the ideal ride height depending on load, and use of driving.

Add Springs: As per the CHOSEN springs and after adding that carefully follow all instructions are given by manufacturer.

Try it out: Test where your truck when you go on a spin to determine how well the springs work and make adjustments if they are not providing an acceptable ride.

Spring Adjustment - Things to Keep in Mind

While adjusting truck springs, some significant factors to consider are:

Strength Select springs based on the weight your truck will be carrying for proper support.

Terrain: Select springs that can take the landscape you will be driving in.

Ride Height - Setting ride height which affects handling and ground clearance

Service: Properly service the springs with lubrication, check-ups and replacing them on time before they become damage ensuring that your door is functioning at its best.

There are several different types of truck springs, and each has its own pros/cons:

Leaf Springs: Well known for being durable as well as inexpensive, but others may notice a more rough ride.

Coil Springs: Higher cost, but they provide a smoother ride and increased handling.

Air springs (adjustable height, softer ride quality and more expensive).

Truck springs can suffer from common issues such as sagging, breakage and squeaking - all of which most commonly be fixed with:

Saggy: Adjust springs up to factory ride height

Breakage: Broken springs should be replaced immediately to help prevent damage to the rest of your car's suspension system.

If they start to squeak, you can add a silicone based lubricant or look into replacing the springs.

One of the most important aspects of a ride is your truck springs and they can help with not only making sure that you have an even drive, but can also adjust some balance to heights as well if its pull or push. Knowing what your truck springs do and how to tweak them for peak performance in turn helps you increase overall efficiency, safety, comfort during drives.

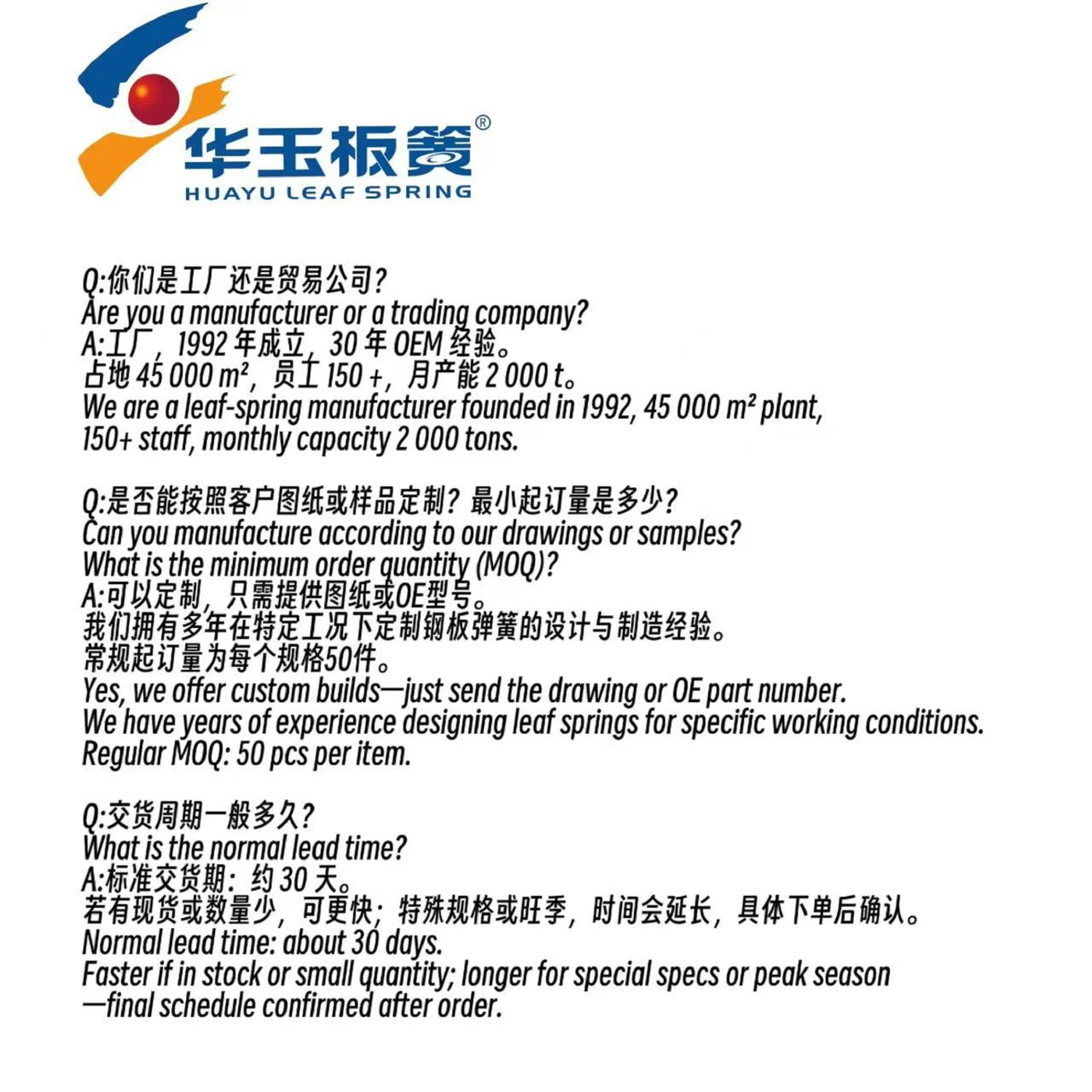

With more than 30 years of experience, we excel in making a springs on a truck of air suspension links, parabolic leaf springs, as well as traditional leaf springs. Leaf springs are available here for light trucks, heavy trucks or trailers.

We continually strive to improve our plant management system, and also, while we seek certifications like IATF16949 springs on a truck, and ISO 45001, we are determined to continue technological innovation and great development for providing excellent customer service to each and every person on the planet.

Currently, we have a annual production capacity of 30 thousand tons, which is a huge supply springs on a truck. Committed to becoming a leading ODM, OEM and end customer service provider, our skilled team adheres to the principle of "customer first" and responds to customer inquiries within 72 hours to meet any customer requirements.

We purchase high-quality raw and springs on a truck components, undergoing a strict quality certification process, the use of advanced production equipment and thorough testing means, total quality control and oversight to guarantee that our products meet customer expectations in terms of size, performance and appearance.

ONLINE

ONLINE