You see, RC leaf springs are a necessity in order for your toy car to be able to give you the fun of driving over rough terrain as smoothly. These springs are intended in a manner for the toy so that it be can able to bounce back quickly from its playtime interaction minor bumps or jumps. It consists of curved strips, usually contiguous and are placed horizontally throughout the stack as a separate component. The comfort of the ride is important as well, and fewer springs will produce a harder bumpier contact with the road surface more than higher number of spring while an increase in over all weight to be distributed by each wider looking tire can improve performance because heavier car moves off line dampening unevenness on bumpy terrain.

There are a few simple steps you can follow for successfully installing your RC leaf springs in toy car. To begin with you need to un-install any shocks that are already in position. After which, you can deploy the replacement RC leaf springs and tighten them in place using screws/nuts. After completing a build of the toy car, I would encourage you to head out and take it for a test spin after installing these new springsilters, making adjustments based on how your improved springs affect the performance.

In order to ensure your RC leaf springs are performing at their best, it helps to be able to tune the height of you Leaf Springs and tailor how they perform through preload5 as well adjusting Dampening. Height refers to how high off the ground the car sits, preload is a measure of spring compression at rest when not driving (which helps with an immediate response), and damping measures resistance during both compression and rebound.

There is a wide variety of RC leaf springs on the market, each have their own pros and cons. For instance, progressive springs are soft initially but progressively stiffen as they compress. Linear springs remain the same stiffness regardless of how far they are compressed, whereas non-linear springs get softer as they are more compressed. Material & DurabilityWhen trying to decide what type of spring you use, it is also important that we look into the material and durability factors. Metal springs are heavy but durable, although strength training is available in metal or plastic.

For reliable use of your RC leaf springs for a longer period of time, it is advisable to follow maintenance schedule. This means of cleaning the springs following its use and carrying out regular inspection for any signs of wornness or damage. If the springs go too soft or hard, you would have to replace them for best performances. Also, you should check other parts of the toy car (like tires and shocks etc) to make sure all body stuff works.

Replacing your RC leaf springs when needed is important in keeping your toy car running at its best. Some signs requiring the springs to be replaced are damage or excessive wear that may impair functioning of the spring seamlessly. However, if the toy car looks like it is too bouncy or so hard riding that your child will not play with it, try a new type of spring. The springs should ideally be replaced on both sides at a time, keeping the stiffness levels more or less consistent for maximum efficiency.

Objectively, RC leaf springs are one of the more important components to a toy car performance; in addition they will also provide to realism and probably an extra level to driving experience. Learning about the installation, adjustment methods and maintenance protocols of these springs should help you enjoy your toy car for an extended period. By comparing the various kinds of rc leaf springs and identifying when it is time to change, you can more easily determine what will enhance your ride.

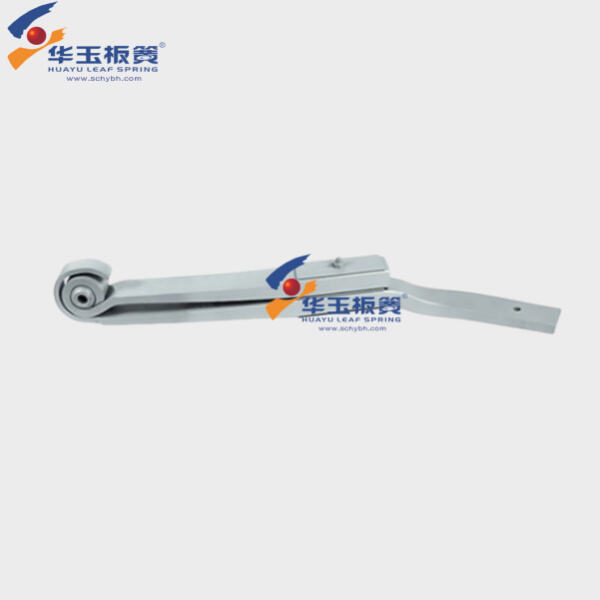

We buy high-quality raw and auxiliary components, undergoing an exact quality-control rc leaf springs using the latest production techniques and an extensive examination means total quality control and supervision, to ensure that our springs meet or exceed expectations of customers in terms quality, size, and performance.

We are committed to rc leaf springs exceptional service to every client and we are constantly developing our technologies and obtaining certifications such as ISO14001 and IATF16949 and ISO 45001.

Today, the company has a rc leaf springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

With over rc leaf springs years of experience, we are experts in making a variety of air suspension links such as parabolic leafspring as well as traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks and trailers, light trucks, or even heavy trucks and trailers, you will find the perfect fit here.

ONLINE

ONLINE