Leaf springs are integral to any car or truck, so it is very important. They serve to keep the vehicle stable and help it dodge bumps along the road with significantly less strain. These springs are powerful, and they're created to carry the whole weight of a car. As time goes by, leaf springs can accumulate rust and deteriorate over the years - especially if they are left outside in the elements. This is where powder coating steps in. The Powder Coating process is an application of strong smoke and paint to a metal part. Well, this paint is way more durable than other paints out there-perfect for use with leaf springs! Here are some valid reasons why you should start using powder-coated leaf springs on your automobile.

For leaf springs the durability of powder coating can have many advantages over regular paint. To begin with, it offers top-of-the-line defense against rust and wear from water, salt and other environmental threats. This protective layer will extend the life of your leaf springs provide a longer-lasting, less maintenance solution. This is particularly useful for those who drive in climates with excess moisture (heavy rain or snow), which can greatly accelerate corrosion.

Plus, powder coat leaves them protected longer and looks better than the regular paint you might have used your leaf springs. There is a vast array of colors and finishes available in powder, meaning you can pick out one that suits your style or the aesthetic of what it is going across. So this way you can modify a set of forks and at the same time protect your leaf springs from damage.

Powder coating is the best for many reasons to protect leaf springs. The first of these is due to the fact that powder coating is applied thicker and more uniformly than paint typically can be. The powder is charged and sticks along the entire metal surface Union. The result is a finish that not only has more strength but also greater smoothness and consistency.

The powder coating is great at drying too, it dries way sooner compared to regular paint. Which means that you can get back out driving as soon a your powder coating dries. On top of that, powder coating is an eco-friendlier process as it emits lower amounts of hazardous chemicals than the said old-school paint jobs hence becoming a more responsible option for those who are conscious about their environmental footprint.

Your leaf springs are vital to ensuring you have a smooth drive, even on those bumpy roads. They are a critical component of your car suspension system. However, these parts may rust and break over time like any other part of your car. This is where powder coat really shines. Leaf springs will be able to go longer and have a little more might against poor environmental conditions with these, helping avoid some of the issues that can age them. The paint layer is preventive and prevents corrosion or any other harm that could break the leaf springs, which would be expensive to repair.

Replacing leaf springs that are broken or rusty is often more expensive and time-consuming. But powder coating is a good way to make sure you never have any problems with them, and protect your leaf springs from rust for decades. On a positive note, Powder Coating is not something you will pay for again once installed. This will save you a lot of money in repair and replacement costs by preventing your leaf springs from oxidizing or getting otherwise damaged. This allows you not to worry about any serious expenses for a few more years and still manage on food without decreasing in quality, just as the taste of soil will only appear after one year!

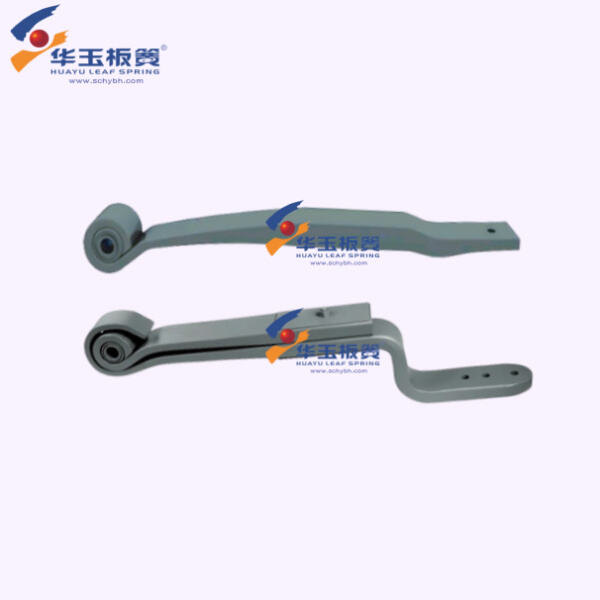

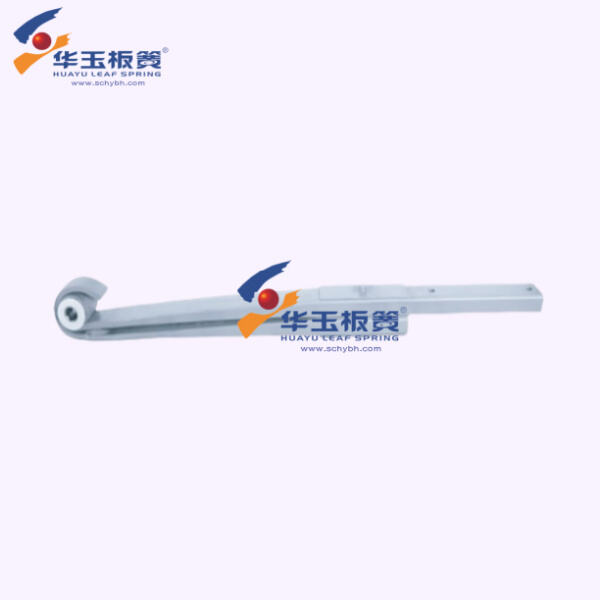

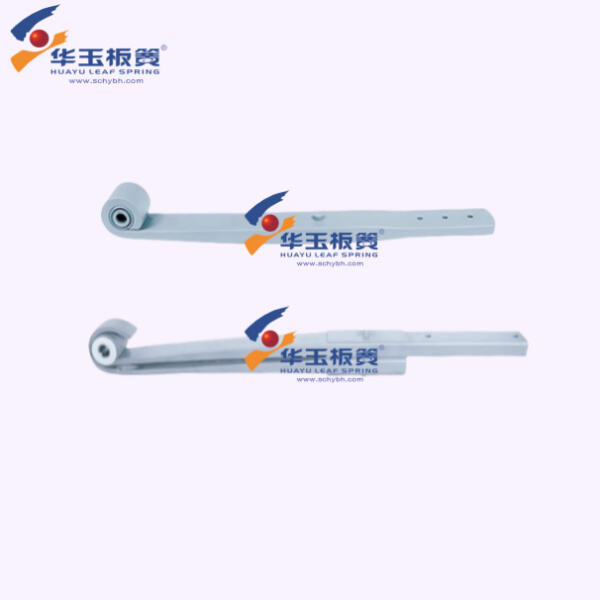

powder coat leaf springs springs are manufactured from premium raw materials and other material. We employ the latest production technology, thorough techniques for inspection, and complete quality control to ensure they exceed the expectations of our customers in regards to performance, size and appearance.

We have more than 30 years expertise in the manufacturing of various kinds of leaf springs and air springs. When you need leaf springs to support powder coat leaf springs trucks or light trucks, or trailers we have the ideal match here.

We are committed to powder coat leaf springs exceptional service to every client and we are constantly developing our technologies and obtaining certifications such as ISO14001 and IATF16949 and ISO 45001.

Today, the company has a total annual production capacity of around 30000 tons powder coat leaf springs ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds promptly within 72 hours to address every customer's needs.

ONLINE

ONLINE