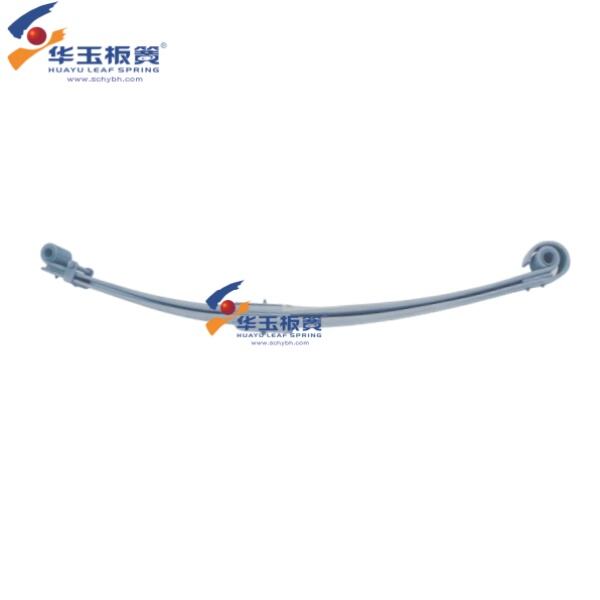

Parabolic leaf spring is a special form of a leaf spring that acts as a buffer to allow the effective operation of vehicles. This type of spring differs from other leaf springs because its shape is not straight or flat. Let’s find out why parabolic leaf springs are used in modern vehicles.

Parabolic leaf springs do an excellent job of distributing the vehicle’s weight uniformly. It reduces stress and helps enhance the vehicle's performance. They are also lighter and more compact than conventional leaf springs, which is why many modern cars employ them.

One factor to explain why parabolic leaf springs are so common, is their comfort of driving. They're specially designed to be more flexible and adaptable, which means a smoother ride. That means there are fewer bumps and jiggles for passengers over and above a smoother ride for the journey.

The addition of the parabolic leaf springs gives added ride comfort, better stability and more control. They are engineered for precise vehicle control and ride comfort, and are relatively easy to install reducing body roll and smooths out bumps. That is, it provides a more comfortable ride for passengers.

Parabolic leaf springs are absolutely critical in determining a vehicle’s overall ride and safety. They’re useful for grip, comfort, and power, and they make for a swift and stable ride for passengers. Meanwhile, this is the reason why HUAYU designs and provides parabolic leaf spring for many passenger cars.

Parabolic leaf springs continuously strive to improve the management of our plants and also, while we seek certifications like IATF16949 ISO14001, and ISO 45001, we are also committed to continuous technological innovation and superior technology in order to provide top-quality customer service to each and every person across the globe.

We purchase high-quality Parabolic leaf springs and auxiliary components, undergoing a strict quality certification process and the use of cutting-edge production equipment and thorough examination means total quality control and supervision to ensure that our springs exceed expectations of customers in terms dimensions, performance and aesthetics.

Today, the company has a Parabolic leaf springs annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

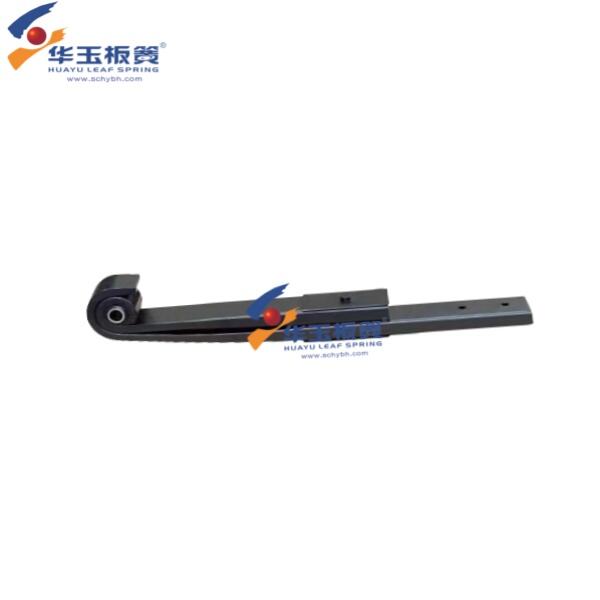

With over Parabolic leaf springs years of experience, we are experts in making a variety of air suspension links such as parabolic leafspring as well as traditional leaf springs. No matter if you require leaf springs that are suitable for heavy-duty trucks and trailers, light trucks, or even heavy trucks and trailers, you will find the perfect fit here.

ONLINE

ONLINE