The mechanical minded would equate an overload spring to a coil or leaf which aids in assisting machines with heavy lifting. They're made out of metal and have a slight flex. It is this bending which gives it its strength to lift so much weight. The overload spring compresses when a machine is too heavy. The squeezing action no more ensures the safety of a machine that is about to lift it then does releasing an angry pitbull after being locked up for 8 hours help stop some damage!

Overload springs are used in large machines such as cranes and forklifts. Even though these machines are designed to lift extremely heavy objects, occasionally they may attempt to carry more than their capacity. In the case where this occurs, an overload spring comes in to make sure that everything stays safe and running just fine with the machine.

There are instances when things might all-of-a-sudden start to get very heavy on machines. In other words, a conveyor belt carrying products may suddenly begin to fill up with product much more swiftly. An overload spring that will aid the machine to cope with these quick and weighty changeovers without having them snap apart.

PR-operating with the right parts: Every time you change parts on your machine, always make sure to use something that will be a good match with the scare spring. If you replace a spring with the wrong parts, it can also prevent the machine from operating.

Forklifts: Forklifts are designed to bear heavy loads, but the incorporation of an overload spring ported into this second line foils any chances if you have loaded above capacity. This helps you to avoid any freak accident and keep it operating properly.

Springs are also a common failure: An overloaded spring may eventually break due to fatigue or other reasons. If it occurs, the only solution is to replace an old spring with a new one. This changes will return the security feature of machine.

Incorrect spring selection: If the overload spring that has actually been picked is not ideal for the machine then it would stop working to offer defense as necessary. These techniques involve correctly selecting the spring type that aligns with what best fits the needs of machine.

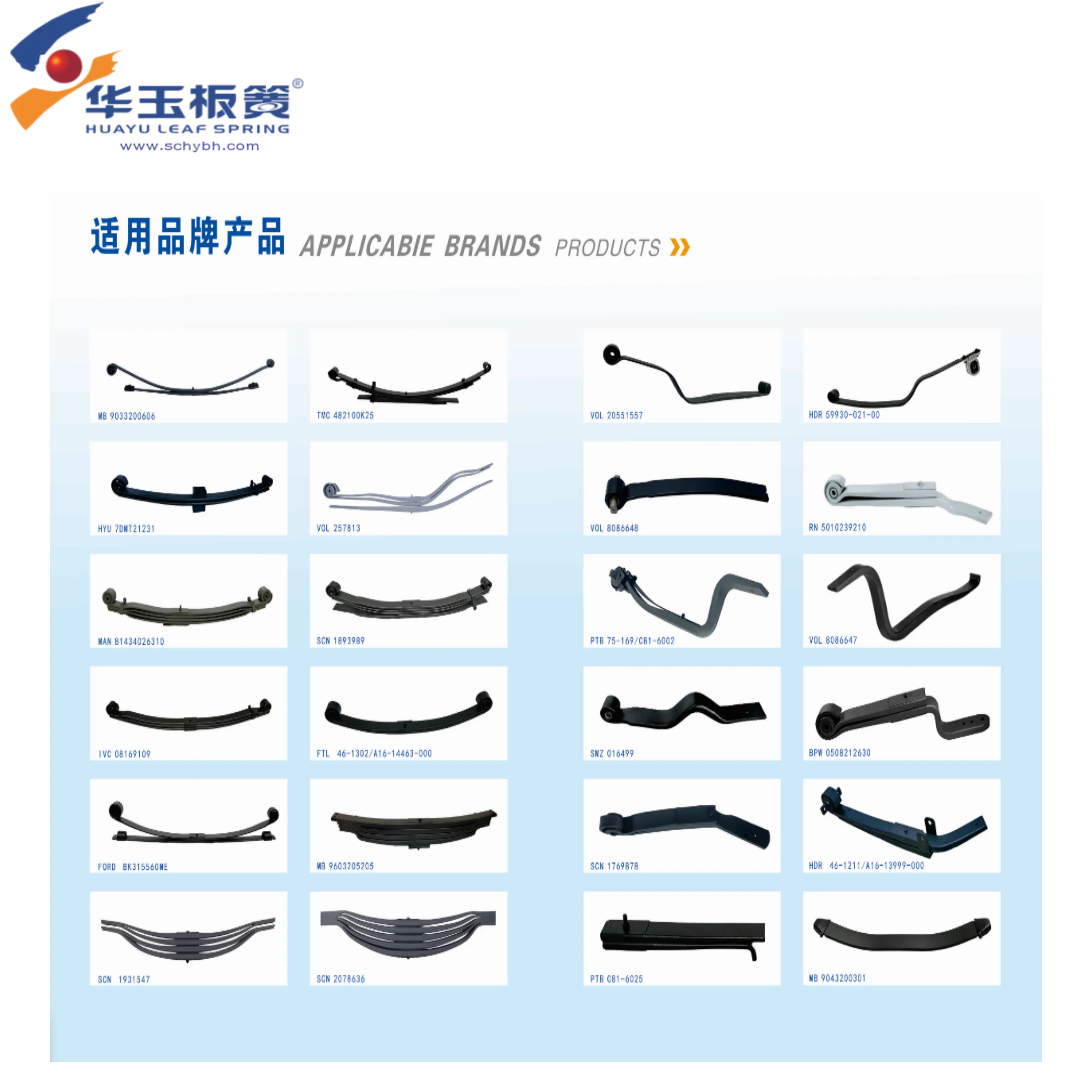

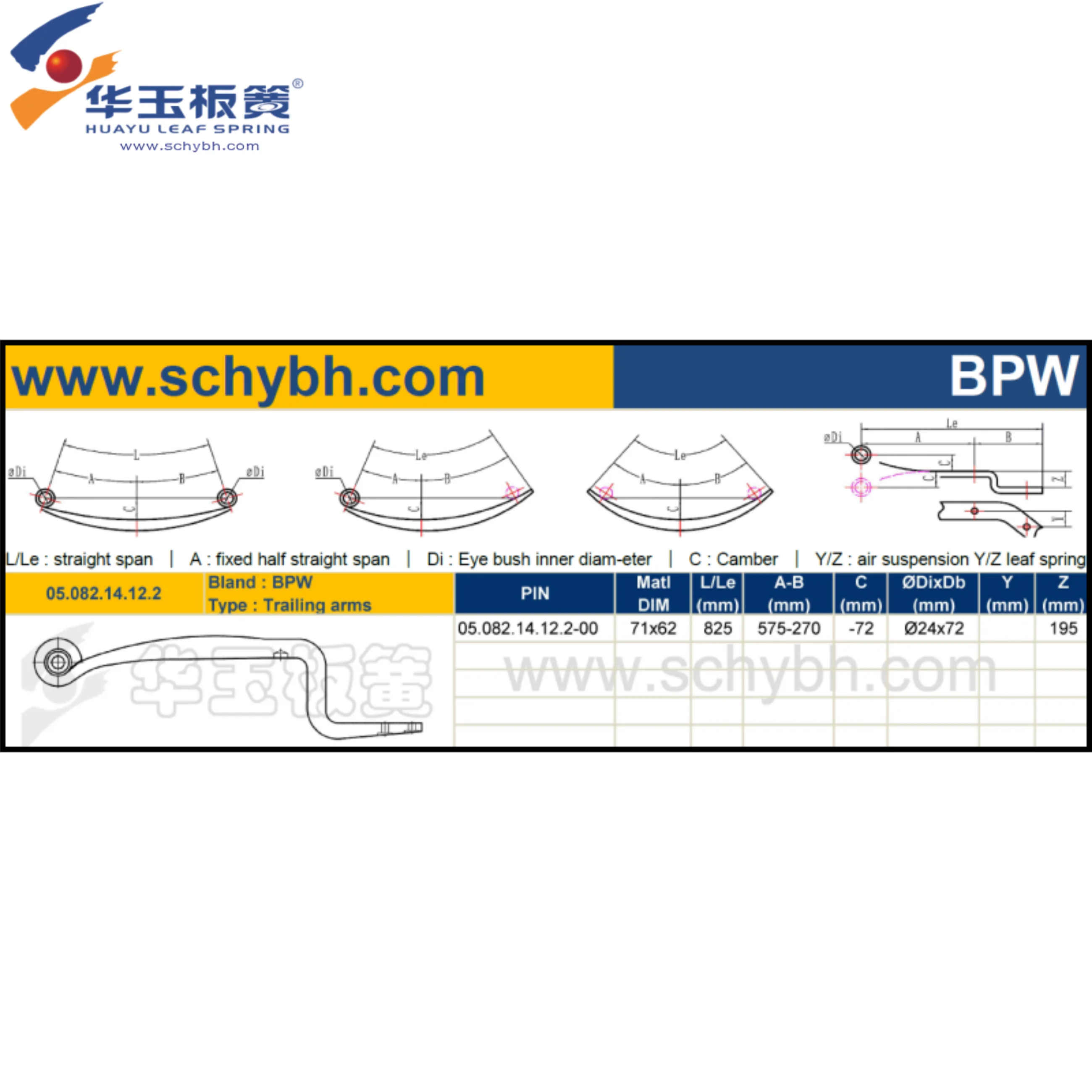

We overload spring more than 30 years experience in the manufacture of a variety of leaf springs and air springs. You can find leaf springs for light trucks, heavy trucks or trailers.

We source overload spring raw and auxiliary material, following a an extremely rigorous quality certification process that makes use of the most advanced production equipment and thorough inspection means, absolute quality control and oversight, to ensure that our springs exceed the expectations of our customers in terms of quality, size, and performance.

We constantly strive to strengthen our plant management system, and while obtaining certifications such as IATF16949, ISO14001, and overload spring, we are also committed to continuous technological innovation and great development to offer excellent service to all customers anywhere on earth.

Our skilled team is committed to be a leading ODM as well as an overload spring service provider. They follow the premise that "customer is first" and can respond within 72 hours.

ONLINE

ONLINE