Importance of Leaf Springs Discount Semi Truck Parts for Heavy Duty Performance

18 wheelers-also called semi trucks or semitrailers-are large commercial vehicles which are essential for transporting goods long distances. Those trucks have to work well, so they use robust parts. Of these components, leaf springs are a must. Without these custom springs, big semi-trucks would fail to transport their heavy loads or maneuver easily on sporadic terrain.

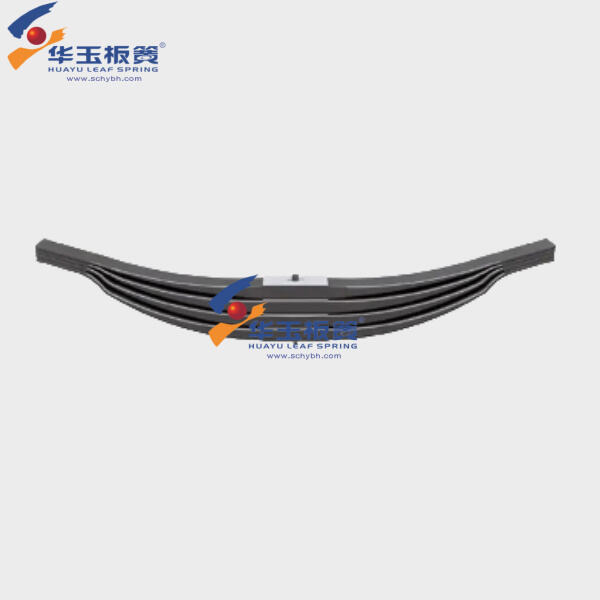

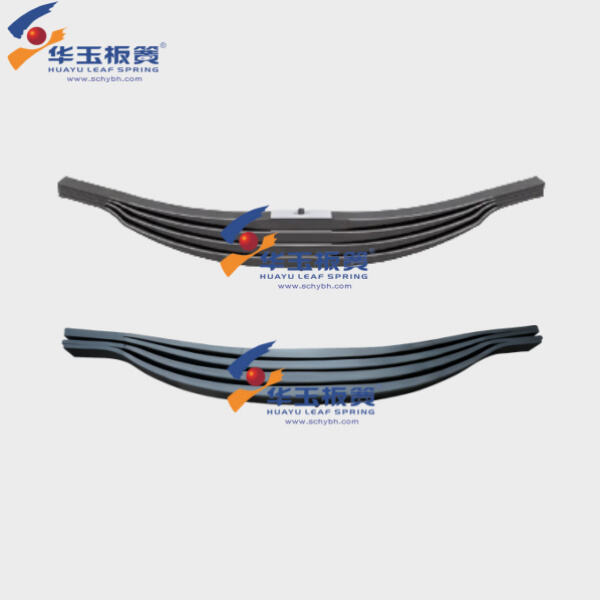

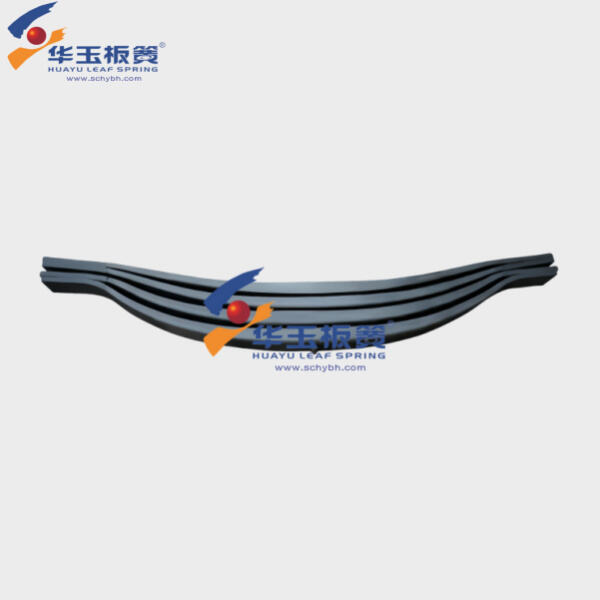

Leaf springs are long, curved pieces of metal leafs gentlyewing stacked in perfect order and secured by a center bolt. They hold up your truck to stabilize it and provide support. As the truck drives over bumps in the road, these leaf springs squeeze together and rebound apart when hits have been diminished to make for a less jostling ride quality. They likewise keep the truck leveled when it has been stacked up with freight.

Steel and composite materials are just a few of the choices you have when selecting material for leaf springs. Steel has been known for its sturdiness and longevity but it is also heavy and rusts over time. Another option is a composite material, which is light and doesn't rust but may not last as long as steel. Decide on the leaf springs after checking aspects such as how much load will be placed in this truck and whether it is exposed to different weather conditions.

Heavy duty semi truck leaf springs can take their toll over time. Indications of wear can be as minor cracks or rust on the springs to a more pronounced sagging, and you may even notice an irregularity in your truck bed. The effects of any one of these could mean consulting with a professional for an evaluation and/or repair to the springs. However, driving the truck with bad or broken springs can be a safety hazard and add further damage to your vehicle.

To maintain your semi truck leaf springs in an optimal condition, use the best practices. Things like overloading the truck, driving carefully on bumpy roads and getting routine inspections of your springs. Besides, quick replacement spend and also broken springs is essential to avoid potential damages as well as crashes codes.

Lastly, if we keeps the importance of semi leaf springs in mind, leaves are responsible for keeping all that heavy-duty performance put together. Through the function of its parts, smart material selection, early detection tricks for deterioration and thus also maintaining a level ground can help preserve your tipper truck to be functional both efficiently and safely over time.

Today, the company has a total annual production capacity of around 30000 tons that will provide ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our professional team semi truck leaf springs to the principle of "customer first" and responds promptly within 72 hours to address any customer requirements.

We source semi truck leaf springs raw and auxiliary material, following a an extremely rigorous quality certification process that makes use of the most advanced production equipment and thorough inspection means, absolute quality control and oversight, to ensure that our springs exceed the expectations of our customers in terms of quality, size, and performance.

We continually strive to improve the semi truck leaf springs of our plants and also, while we seek certificates such as IATF16949 and ISO14001, and ISO 45001, we are dedicated to continual technological advancement and superior development to provide excellent customer service to each and every person on the planet.

With more than 30 years of experience, we excel in making a semi truck leaf springs of air suspension links, parabolic leaf springs, as well as traditional leaf springs. Leaf springs are available here for light trucks, heavy trucks or trailers.

ONLINE

ONLINE