Back in the day, there was a particularly unique type of spring: a "leaf spring." “ Did you ever wonder what is a spring? A spring is an elastic object which can bend and flex but everytime you stretch (or push) it, the material will return to their original shape or state. One of the more important components are leaf springs which often found in vehicles you see everyday like cars and trucks to allow them operate at their maximum efficiency level.

One of the oldest types of suspensions is leaf springs that have been used all over the world and even in ancient times. The first applications were for carts, and wagons to assist with loads making it easier on people. These soon were followed by leaf springs in your classic cars we who are right drive each day. Leaf springs: Leaf spring is the only type of suspension that delivers linear resistance, as it consists of several heat treated layers of metal bolted in together very snugly. Zel Rosso Leaf Blower Vacuum CollectionThese are what you call the "leaves" and it is these layers that have been formed to be narrower at one end than the other (i. The spring also has a natural curve, which is important in its functioning. The layers are then sandwiched together and held in place by a central bolt.

Leaf springs are very functional, as they help to ensure a smooth ride when driving over potholes and rough patches on the road. As a vehicle drives over bumps or potholes, the leaf springs bend and adjust to absorb some of that shock. It helps absorb shock and provides a smoother, more comfortable ride for everyone in the car. The vehicle is further held to the road by its leaf springs. When a vehicle corners, it leans into that corner; the leaf springs assist in this motion. Gear change is also very stable, when turning or on the uneven roads without worrying about rollover and out of control.

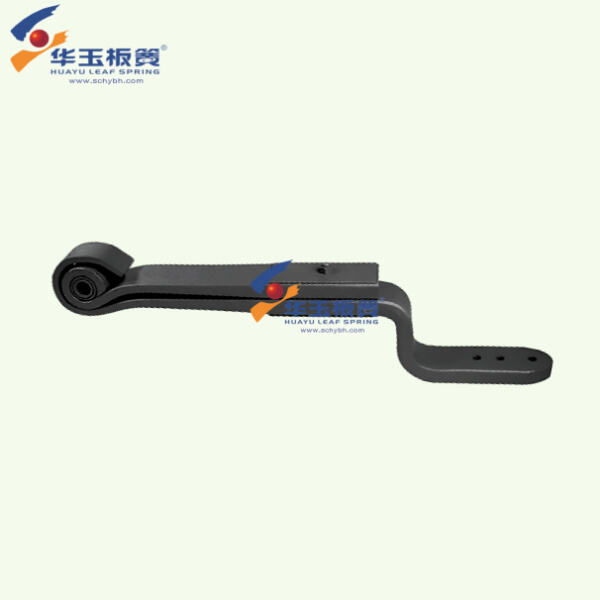

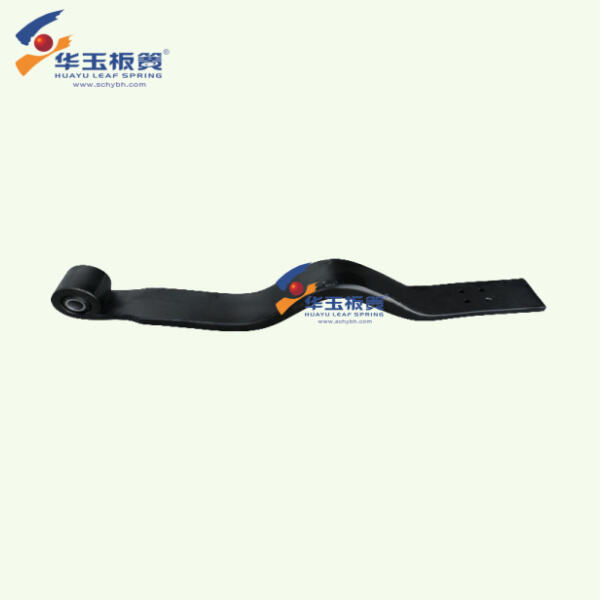

Leaf springs are of a few different types and features, as mentioned below at the line ends; this makes them quite unique. The former is referred to as the "mono-leaf spring. This is constructed from a curved, single flat piece of metal. Mono-leaf springs are usually used in smaller cars as they are simpler and less expensive to manufacture. The second one is the common style of leaf spring known as a "parabolic leaf. Practically speaking, this consists of several layers in a leaf spring that do not have the elongated form used by conventional flat springs. This unique shaping allows for the parabolic springs to flex more and do a better job of taking shock as opposed to traditional leaf-spring designs. Finally, the “multi-leaf spring.” The center of this kind is layered, with shorter layers going towards the inside. A more advanced version of this is the design shown below, which adds even additional strength and stability to the spring so you have fierce control over your firing behaviour.

Just as any other part of a vehicle, leaf springs are subject to wear and tear over time, for the reason that they do get employed. Worn leaf springs can lead to problems when it comes to the way a vehicle drives. Leaf springs should be inspected by a mechanic periodically to help maintain them in good condition. Mechanics who should be looking for signs of damage, cracks or deterioration. In addition, they verify that the bolts securing together these layers are still snug. If something wrong with the leaf springs is found, they can often be repaired or replaced. One of the most important thing one needs to keep in mind is leaf springs are under stress and if not handled appropriately could be dangerous so it advised never try repairing them by yourself.

New materials are also an aspect in which leaf springs can develop through technology advancements. Modern cars often see leaf springs constructed from more advanced materials such as fiberglass or carbon fiber. The use of composite materials makes these springs lighter and more flexible than conventional metal leaf springs, which could aid fuel efficiency as well the ride quality. Some companies are even testing “active” leaf springs, where the rate of stiffness can actually be changed per driving condition. In other words, the leaf springs could be throttled up or down depending on how you are driving so it may lead to even better handling and ride quality.

Today, the company has a total annual production capacity of around 30000 tons a leaf spring ample supply capability. Committed to become a top ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds promptly within 72 hours to address every customer's needs.

We have over 30 years expertise in the a leaf spring of various kinds of leaf springs and airspring. When you need leaf springs for heavy-duty trucks or light trucks, or trailers we have the ideal match here.

We source a leaf spring raw and auxiliary material, following a an extremely rigorous quality certification process that makes use of the most advanced production equipment and thorough inspection means, absolute quality control and oversight, to ensure that our springs exceed the expectations of our customers in terms of quality, size, and performance.

We are committed to a leaf spring exceptional service to every client and we are constantly developing our technologies and obtaining certifications such as ISO14001 and IATF16949 and ISO 45001.

ONLINE

ONLINE