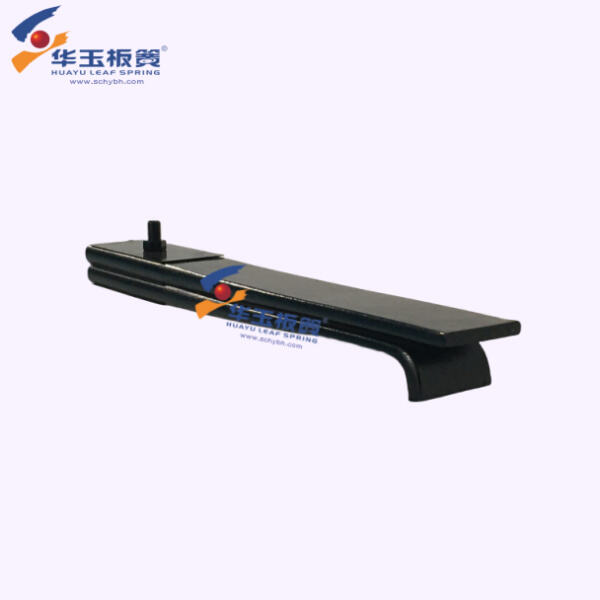

Kommer du ihåg synen av en bil som drog en annan bakom sig? Om du gör det, bevisar det precis hur viktigt en stabil släp är. En instabil släp kan orsaka att den dragningsfordon som börjar svänga från sida till sida, vilket är en recept för katastrof. Detta är något som bilsläpar fördelar med hjälp av bladfästen. Bladfäste: Ett bladfäste ser ut som en hop blad och är ett långt, flat stycke metall som används under bilar eller släpar. Dessa är en kritisk komponent eftersom de hjälper till att hålla din släp i balans när du släpar den från plats till plats.

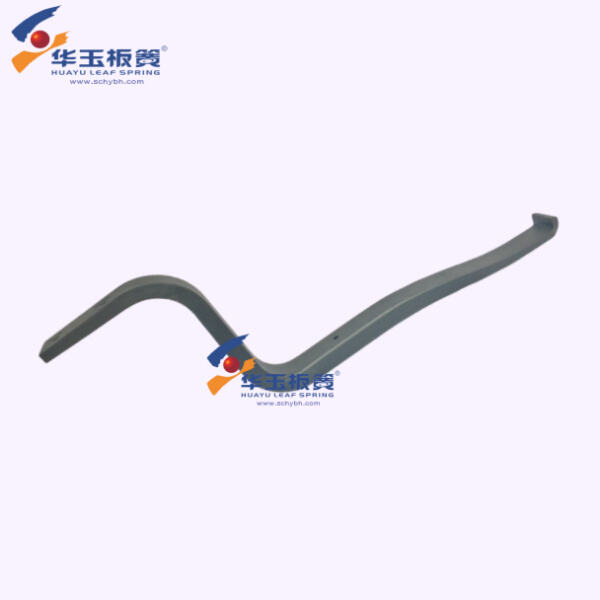

Sådana fjäder är mekaniskt utformade i olika typer med olika dimensioner. Dess uppgift är att bära den tunga lasten och distribuera den korrekt över både ärv och bil. På det sättet, när du lägger alla dina tunga saker i ärven, stör det inte balansen när det gäller att bli släpt. I de flesta fall, om din bilärva ser gammal ut, bör den ersättas med nya fjäder. Lyckligtvis är de ganska tillgängliga och du kan få en på nästan varje bilaffär för din bilärv fjäder. Om du måste byta hjulmutter Original Equipment-märke är det enkelt att byta ut via användning av en gummiask på varje hjulnacke.

Varför du bör uppgradera dina bladhjul En av fördelarna är att det hjälper till att säkerställa stabilitet bakom dig när du släpar, vilket gör din biltrafik säkrare. Ju stabilare för trailern = smidigare åkande i ditt fordon. Som man kan förvänta sig är bladhjul högkänsliga för rost och vanlig utslitas på grund av den dagliga misshandlingen de utsätts för. När de inte gör det, betyder det att förmågan att uppta slag från saker som vägen nästan inte finns, vilket resulterar i ett mycket mindre smidigt (och bumpigare) åkande än vad du vill ha. Det påverkar hur trailern släpas, men det kan också leda - med tiden - till snabbare däckutslitage eller dyrrare problem senare.

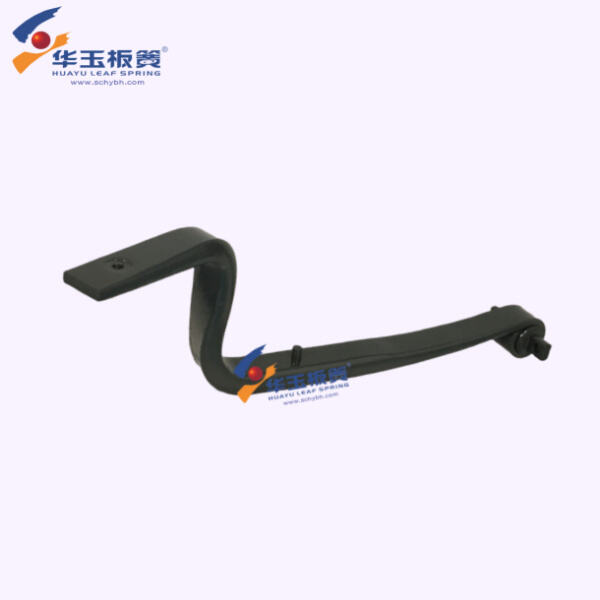

Om du kör längs vägen eller trycker hårt på bromsarna, håller fjäderblad allt i släpet stabil. Handtagen tar upp backar, dalar eller hål i vägen som annars skulle ha gjort ditt släp vacklande eller snedvridet. Tänk bara på hur mycket stress i ditt liv du skulle ha om saker runt omkring var så bräckliga som glas och keramik, saker som bara faller av eftersom fjäderbladen inte är tillräckligt mjuka. Och det är bara irriterande!! För att säkra lasten, håller två platta fjäderblad ner den.

Fjädrar av olika typer används i olika slags släp. Var och en av dessa är utformad för att uppnå något annat, och de består vanligtvis av stål eller andra sammansatta material som har sina fördelar. Stålfjädrarna är billiga och robusta och kan därför stödja tunga laster utan att materialet viker. Samtidigt kan sammansatta fjädrar användas i vissa tillämpningar eftersom de både är lättare och fria från rugg, men detta är inte en vanlig lösning. Välj den lämpliga fjädern för din släps bärkapacitet och varulast.

För närvarande har vi en årlig produktionskapacitet på 30 tusen ton, vilket är ett stort utbud av bladfjädrar till bilsläp. Med ambitionen att bli en ledande leverantör av ODM-, OEM- och slutkundstjänster följer vårt skickliga team principen "kunden först" och svarar på kundförfrågningar inom 72 timmar för att möta alla kundkrav.

Våra bladfjädrar till bilsläp är tillverkade av högkvalitativa råmaterial och andra material, och vi använder den senaste produktionstekniken, noggranna inspektionsmetoder och komplett kvalitetskontroll för att säkerställa att de uppfyller eller överträffar våra kunders förväntningar vad gäller prestanda, dimensioner och utseende.

Car trailer leaf springs strävar hela tiden efter att förbättra ledningen av våra anläggningar och samtidigt som vi söker certifieringar som IATF16949, ISO14001 och ISO 45001 är vi också engagerade i kontinuerlig teknologisk innovation och överlägsen teknik för att erbjuda toppklassig kundservice till varje enskild person över hela världen.

Med över car trailer leaf springs års erfarenhet är vi experter på att tillverka olika typer av luftfjädringslänkar, såsom parabolformade bladfjädrar samt traditionella bladfjädrar. Oavsett om du behöver bladfjädrar som är lämpliga för tunga lastbilar och släp, lätta lastbilar eller till och med tunga lastbilar och släp, hittar du den perfekta passformen här.

ONLINE

ONLINE