|

🔹 Price |

$33.38-41.72 / PC (EXW,MOQ 50) |

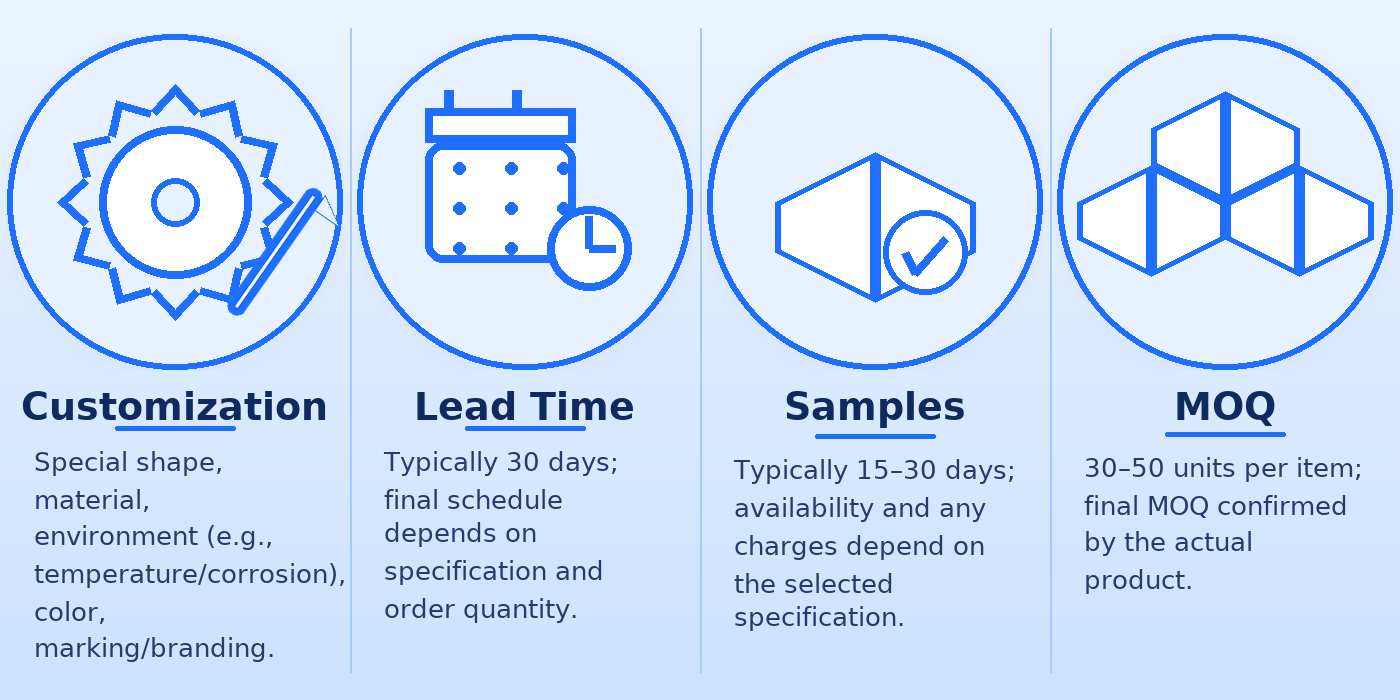

| 🔹 Price Note | Price is for reference only.Final quote varies by spec,quantity,destination and freight.Pls confirm with us. |

| 🔹 Brand | Peterbilt |

| 🔹 MOQ | 50 pcs |

| 🔹 Lead Time | Typical lead time: ~30 days. Custom builds may require additional time. |

| 🔹 OE Number | C81-6025 |

| +86 157 3155 7100 WhatsApp | |

| [email protected] |

| Scania,Volvo,Mercedes-Benz,VolkswagenSchmitz,SAF,ROR,Renault,Man,Iveco,Ford,DAF,BPW,Peugeot,Kassbohrer,Fruehauf,Fiat,Citroen | |

| Freightliner,LaFrance,Sterling,Oshkosh,Western Star,Hendrickson,Volvo White,International,Peterbilt | |

| FAW,JAC,Dongfeng,Shacman,Sinotruk |

We continuously strive to enhance our factory management system to meet diverse regional requirements while obtaining certifications such as IATF16949,ISO14001,and ISO45001.

| Certificate | Certificate Name | Description |

|---|---|---|

|

ISO 14001 Environmental Management System |

Ensures our production complies with environmental protection standards during the manufacturing process of automotive leaf springs. |

|

IATF 16949 Quality Management System |

International standard for quality management in automotive production, covering both parabolic and multi-leaf spring manufacturing. |

|

ISO 45001 Occupational Health & Safety System |

Provides a safe and healthy working environment for our employees, minimizing occupational risks and hazards. |

We offer flexible and efficient shipment solutions to customers worldwide.

Our products have been exported to 35+ countries, covering Europe, Asia, South America, Africa and the Middle East.

| Mode | Description |

|---|---|

| 🚢 Sea Freight | Port of Chongqing, Shanghai, Ningbo, or others in China. Suitable for large-volume and cost-effective shipping. FCL & LCL both available. |

| 🚆 Railway Transport | China–Europe railway service via Chongqing or Chengdu, with fast and stable delivery to major EU cities. Recommended for inland European clients. |

| ✈️ Express Delivery | DHL, FedEx, UPS, SF, EMS, suitable for samples or urgent orders. Typical delivery time: 5–10 working days. |

📦 All goods are packed with anti-rust treatment, stretch film, and strapped on steel or wooden pallets for safe international transit.

▶️ Logistics Video:

| Question | Answer | Function | Picture |

|

1.Will the leaf spring really go the distance? Stop guessing—let fatigue testing call it. 2.One batch is tough and the next is tired—why? Find the root cause and lock the process for steady durability. |

Fatigue Test | We mount the leaf spring on a test rig that pushes and releases it over and over—thousands to millions of times—just like road bumps do.This gives a quick, accurate measure of fatigue resistance without doing long road tests. |

|

|

1.I see tiny cracks on the leaf spring surface or edges—how can we fix or prevent them? 2.Why is the spring cracking early, and what simple steps can reduce that risk? |

Shot Peening | Carry out shot peening strengthening at the leaf spring stretched surface; under the state of prestressing, the even and lasting residual stress distribution can be obtained, and the fatigue life will be improved. |

|

|

1.The spring breaks too soon—how can we boost its fatigue strength? 2.How to reduce the risk of cracking on leaf spring? |

Thermo-mechanical treatment | After heating the leaf spring to the right temperature, we cool it fast in a specially formulated high-speed quench oil. That even cooling turns the steel into uniform martensite through the thickness—giving steady hardness and strength. |

|

|

1.The leaf spring rusts easily in humid or salty conditions—how can we protect it? 2.Coating is uneven or too thin in gaps and corners—how do we make coverage uniform? |

Electrophoretic Primer Anti-Corrosion | Apply electrophoretic anti-corrosion coating + baked topcoat process, with additional primer pre-treatment on irregular surfaces (e.g., edges,) to ensure coating adhesion compliance. |  |

| Image | Packaging Type | Description |

|---|---|---|

|

Steel Pallet | Bundled with anti-rust oil and plastic wrap, placed on heavy-duty steel pallet. Ideal for export with high stacking strength. |

|

Standard Export Pallet | Plastic-wrapped with PET/PE straps. Compact and secure for container loading. |

|

Custom Pallet | Double-wrapped with stretch film and reinforced with horizontal/vertical straps. Suitable for mixed or long-distance shipping. |

| [email protected] | |

| 0086-15731557100 | |

| Sichuan Huayu Vehicle Leaf Spring |

ONLINE

ONLINE