Are you the person who uses a trailer to carry heavy objects such as furniture, equipment or animals behind your vehicle? If so, then the slipper spring suspension would be very useful for you. This unique process of WDH helps in improving the smoothness and safe delivery to your trailer on road. So, why slipper spring suspension systems are the best choice to bear heavy loads in this blog post about those bent leaf springs.

You could think of a suspension as an array of springs that help to dampen the jerk and rattle when there are humps, potholes or uneven surfaces on your voyage. A suspension system in a trailer is important: it minimizes bounce that could cause the load to slide, swing or roll away and possibly ends tipping over which means your cargo will be damaged as well as bumps also ordered vehicle. Slipper spring suspension, a form of leafspringsuspension in general exists to be less expensive and is notably simpler due to the lack-load hardware components required. So, the other key benefits of going slipper spring suspension for your trailer are...

Greater Control: Slipper spring suspension spreads the load evenly to keep your trailer stable and minimize your risk of uneven tire wear, overloading or fishtailing. A stable trailer is easier to drive and handles better in sharp turns, curves or steep grades.

Pictured here are full layers of steel blades, which offer superior strength over others who use the top 5" section furrow flexing giving way to rugged Nebraska terrain. And lower long-term overall maintenance, repair and replacement costs due to the increased durability.

Better ride qualitySmooth riding characteristics comes from slipper spring being able to smoother the impacts shocks and vibrations resulting in less rattles, banging around inside of trailer. The smoother ride means less nausea or fatigue, whether the passengers are traveling with a pet in its cage.

Tailorable Performance: With slipper spring suspension, you can determine how much the springs will compress and rebound (or more accurately stated - tailor the distance traveled by your trailer's chassis up or downward) in response to load requirements. This quick guide will show you how customizing your suspension system can actually do wonders when it comes to optimizing trailer performance and comfort levels.

Slipper Spring SuspensionExplained with Key Components and Benefits For Your TrailerThe slipper spring suspension has all the above advantages we have discussed. The following are the elements of a standard slipper spring suspension system:

Axle: An axle is the rod that supports and connects wheels to a trailer called single or multiple depending on size and weight of the latter.

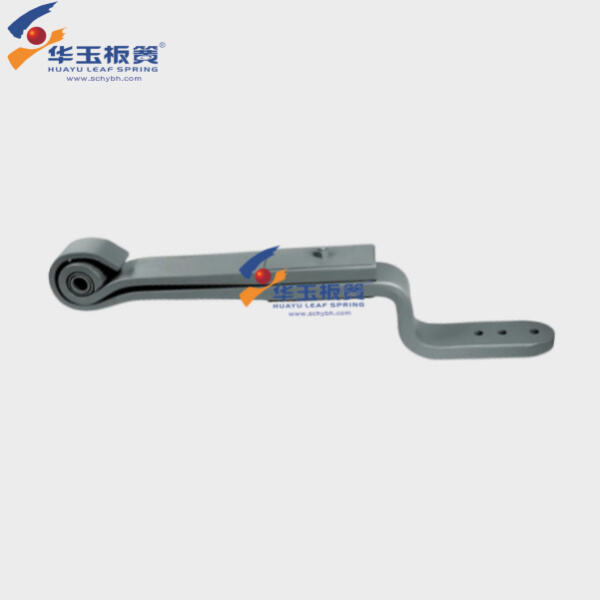

Springs - positioned half per side, these flat-shapes steel blades acts as the dominant suspension components in a slipper spring technique. Attached to an axle at one end and a trailer frame on the other, these blades roll with movement but then flex when they hit something; that energy is stored before being unfurled as you go over the obstacle.

Hangers: The hanger brackets hold the springs and may be adjustable or fixed, depending on the system design.

U-bolts - U-shaped clamps secure the axle to the springs and can be adjusted for changing an axles height or alignment.

Other springs (optional): Other components, such as hydraulic or pneumatic cylinders shocks - dampers that absorb and dissipate shock impulses to which the spring does not respond. While not all slipper spring systems include shocks, they do help improve ride quality and performance where it is needed.

Slipper spring suspension systems come in many configurations, the specifics of which vary based on manufacturer, trailer type and usage requirements. One type uses a single spring per side, while the second includes multiple stacked springs or even angled orientations. For some, there are equalizers in the system that help distribute a load more evenly across several springs. When purchasing slipper spring suspension systems, it is essential to ensure that you purchase a system which matches the weight of your trailer as well its size and configuration. You also need to follow installation procedures properly ensuring timely periodic maintenance thereafter with frequent checkups or any necessary retightening so onATUS-QTS2-000 heavy duty trailer parts are fully functional at all times based upon manufacturer recommendations provided.

Slipper Spring Suspensions are the premier choice for heavy load transportation when it comes.

Excellent Load Bearing: Slipper spring suspension has a simple and durable design, which allows it to carry more weight than other systems with some slipper springs handling as much as 10k pounds per axle.

Greater Flex: The quick flexibility of slipper swing type suspensions is a feature that makes it different from other kinds where due to instability an accident can happen anytime. This flexibility is what makes a slipper spring suspension ideal for off-road or tilted terrain.

Economic Pricing: Other than other spring systems, a slipper suspension with few elements have less servicing and involve lower fees to fix in the long run. In addition, slipper spring suspension can be retrofitted on top of trailers already in service, saving the purchase expense.

You can rely on slipper spring suspension as a cost-effective and quality system to help you haul heavy load with ease. Understanding the advantages, components and guidelines of slipper spring suspension will enable you to make an educated choice on what would best suit your trailer; thus helping generate a smoother trip down the highway. Happy hauling!

Our skilled team is committed to be a leading ODM as well as an slipper spring suspension service provider. They follow the premise that "customer is first" and can respond within 72 hours.

slipper spring suspension continuously strive to improve the management of our plants and also, while we seek certifications like IATF16949 ISO14001, and ISO 45001, we are also committed to continuous technological innovation and superior technology in order to provide top-quality customer service to each and every person across the globe.

We slipper spring suspension more than 30 years experience in the manufacture of a variety of leaf springs and air springs. You can find leaf springs for light trucks, heavy trucks or trailers.

We purchase high-quality raw and slipper spring suspension components, undergoing a strict quality certification process, the use of advanced production equipment and thorough testing means, total quality control and oversight to guarantee that our products meet customer expectations in terms of size, performance and appearance.

ONLINE

ONLINE