A leaf spring is essentially a long flat piece of metal shaped like (you guessed it) a leaf. It is commonly constructed from rugged metals such as steel to ensure rigidity when driving it through the bends. Leaf springs are connected in pairs to the vehicle's suspension system; most cars have two or more. These springs work in conjunction to make the car deal with bumps and irregularities on road.

Leaf springs are there to lessen the bouncing up and down of a car over bumps. When the car goes over a bump of pothole, leaf springs bend this is called deflection. This makes the ride feel better not just for people in their CrossTurismo, but also all other passengers as this bending action softens each impact. This speeds up the vehicle and due to lack of leaf springs makes every jump on a road even more painful back.

However, leaf springs do have their cons. The first thing that comes to mind is the one of their main problems: They are heavy. Then a question for you, have an impact on the total weight of the car and it too extra tonnage +. ~ Heavier cars might not feel as well to drive and could use more fuel. With leaf springs, very high cars can become too heavy or large loads and this also leads to a problem.

Leaf springs play an important role, as they absorb jolts and bumps while the car travels along rocky or uneven terrain. They collaborate with other aspects of the suspension system such as shock absorbers and sway bars. The springs move in response to bumps, potholes and the like while shock absorbers attempt to control that movement. Sway bars hold one side of a car up during turns when forces have it rolling against them too much for comfort. These components all collaborate to offer a comfy journey, even over the rough terrain.

Leaf Springs are no different and over time they can wear out or even break, so replacing them becomes a necessary thing to do in order for your vehicle perform at its best. Car owners and drivers should regularly inspect their vehicle leaf spring for any damage, rust or failed parts that would potentially cause problems with the proper operation of these components. If the leaf springs are in a bad way, they'll need to be replaced for both safety and ride quality.

At times car owners also need to replace there leaf springs with performance csrs for even a better performing vehicle. This could be as simple as going with thicker leaf springs that are rated for a heavier load or adding more leaves to the pack. Upgrading helps drivers add more weight to the car and can also make a variety of improvements in terms of handling.

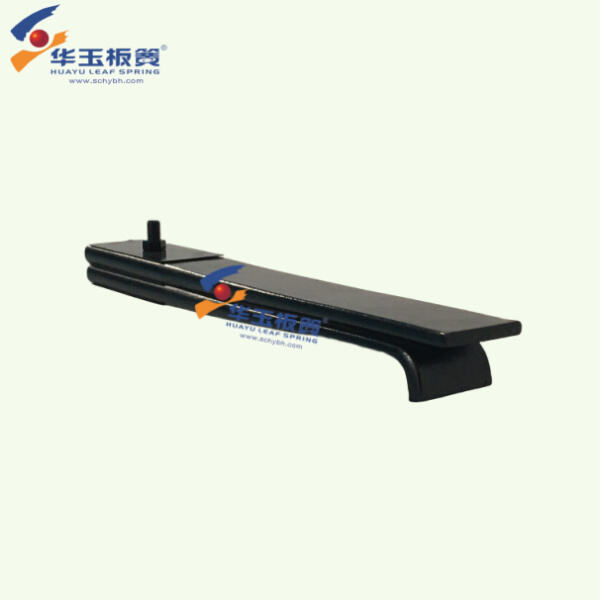

Now, there are several different types of leaf springs designed for cars. They come in several shapes and forms: mono-leaf springs, multi-leaf leaf springs & parabolic leaf spring. A mono-leaf spring is a single leaf, while multi-leaf springs consist of multiple leaves stacked on top of each other. Curved/Taper leaf springs or Parabolic Leaf Springs: It is a type of spring where instead of flat layers (leafs), they are different diameter curved to each other, suitable for more supporting capacity and better flexibility compared with traditional leaves. This choice gives car owners the freedom to select leaf spring type which is most suited for their requirements.

We continually strive to improve the conventional leaf spring of our plants and also, while we seek certificates such as IATF16949 and ISO14001, and ISO 45001, we are dedicated to continual technological advancement and superior development to provide excellent customer service to each and every person on the planet.

Today, the company has a conventional leaf spring annual production capacity of around 30000 tons guaranteeing ample supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our skilled team is committed to the concept of "customer first" and responds to customer inquiries within 72 hours in order to meet every customer's needs.

We purchase high-quality conventional leaf spring and auxiliary components, undergoing a strict quality certification process and the use of cutting-edge production equipment and thorough examination means total quality control and supervision to ensure that our springs exceed expectations of customers in terms dimensions, performance and aesthetics.

With more than 30 years of experience, we excel in making a conventional leaf spring of air suspension links, parabolic leaf springs, as well as traditional leaf springs. Leaf springs are available here for light trucks, heavy trucks or trailers.

ONLINE

ONLINE