So, trucks are large size machines with great importance in our regular life. They can transport very heavy loads, through extremely difficult roads. Ever wonder how trucks manage to keep rolling even under the strain of huge loads? Here's the dirty little answer: axle under leaf springs. This layout is extremely crucial for the functionality of trucks and particularly in this post, let's tell you why that design indicates also exactly how vehicles run far better on a roadway.

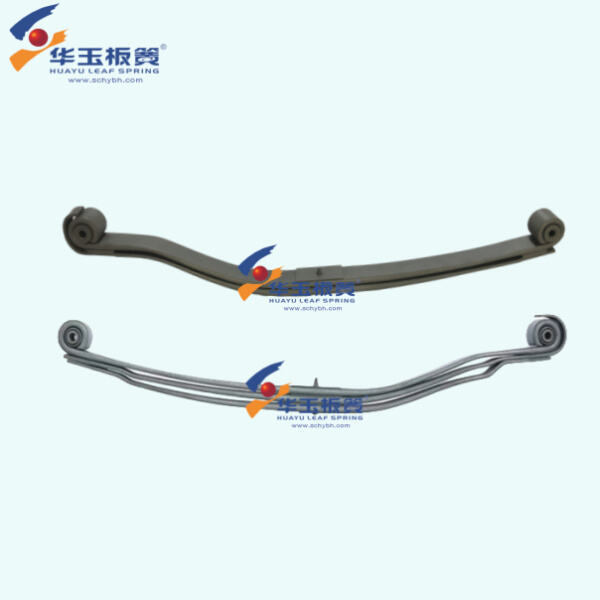

Leaf springs are precisely designed bent metal plates that sit on top of each other. These are employed to supply the truck with a smoother ride and better driving, particularly when there is heavy load underneath. Leaf springs have been around forever because they are simple, cheap and work well. By placing the axle under the leaf springs it gives you an incredibly strong setup which will keep on going even in more testing conditions for higher weight loads.

AxleThe axles is the jet of a truck that allows its tires to spin. Special bolts called u-bolts are used to attach it to the leaf springs. The leaf springs part is a vital one, as these components are what bear the weight of the truck and allow it to bounce down our or your roads. This allows for proper balancing of the truck and gripping mechanism that can grasp onto nearly anything. The leaf springs can then be situated under the axle and this ensures equal distribution of weight along with easier stabilization. It provides a smoother ride, even when the truck is laden down with something heavy.

As the truck goes over rocks, holes or any other obstacle for that matter you will essentially see a leaf spring bending and twisting. This play makes driving more comfortable since playing takes the turbulence from road before it gets to the wheels. As a result, the truck does not need to speed up or slow down too suddenly and it prevents tipping that might endanger both cargo on board. This is credited to the leaf springs that dampen noise and vibration, ultimately allowing for better driver concentration at any given time.

Repairing trucks can become very costly as these are expensive machines. The wonderful thing about the axle under leaf springs design is how cheap and easy to repair it can be. Leaf springs on the other hand are a budget-friendly option as they're made of metal and not typically very expensive to replace. Even if one of the springs breaks are worn out, it can be easily replaced without having to take apart all suspension system.

Leaf springs should be lubricated every so often to prevent rust and friction. Moreover, the bolts and nuts keeping all components of this device intact should be inspected regularly for tightness. Drivers should also keep an eye the truck's elevation along with equilibrium.to ensure no overloading is happening. Simply put, if one thing seems wrong or out of the ordinary with your ride, it can point you in any direction to know for sure what is happening and easily find a problem: just check those leaf springs.

Leaf springs also help distribute the load between front and rear axles of the truck. This also ensures that the load is distributed evenly and not just on one side, which can help improve steering and braking behavior. The leaf springs are also designed to keep the truck's ride height at an equilibrium, not letting it sag too low or pick up too much height which could eventually cause more issues.

We constantly strive to strengthen our plant management axle under leaf springs, and also, while we seek certifications such as IATF16949, ISO14001, and ISO 45001, we are dedicated to continual technological innovation and great development for providing excellent service to every customer around the world.

Today, the company has a total annual production capacity of around 30000 axle under leaf springs, we have a large supply capability. Committed to be a world-class ODM, OEM and end customer service provider, our experienced team adheres to the principle of "customer first" and responds swiftly within 72 hours in order to meet all customer needs.

We buy high-quality raw and auxiliary components, undergoing an exact quality-control axle under leaf springs using the latest production techniques and an extensive examination means total quality control and supervision, to ensure that our springs meet or exceed expectations of customers in terms quality, size, and performance.

We have more than 30 years expertise in the manufacturing of various kinds of leaf springs and air springs. When you need leaf springs to support axle under leaf springs trucks or light trucks, or trailers we have the ideal match here.

ONLINE

ONLINE